#Product Trends

BIG-PLUS dual-contact spindle system now licensed to almost 170 tool manufacturers

Customers may already have this highly accurate, robust spindle interface without even knowing it. BIG KAISER now provides a simple method for quick on-site verification.

Ruemlang, Switzerland – September 17, 2018 – BIG KAISER, a global leader in premium high-precision tooling systems and solutions for the metalworking industries, announces that in addition to an already extensive list of licensed machine manufacturers, eight more have recently become licensed to utilize BIG-PLUS spindle and tooling systems on their machinery.

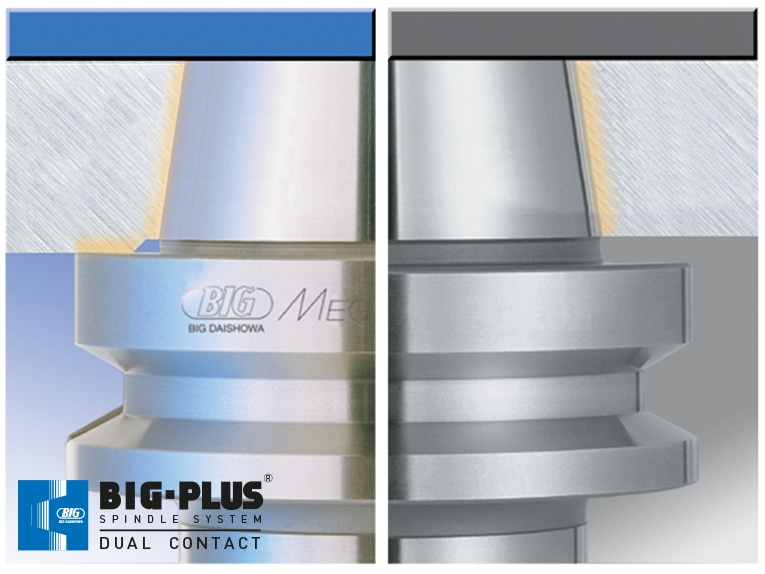

The BIG-PLUS solution is unique and provides substantial advantages over competing industry spindle designs. It is the only system that provides simultaneous taper and flange contact in a 7/24 cone interface. This dual-contact connection between the machine and the tool makes it exceptionally robust, reliable and accurate.

There are now nearly 170 manufacturers licensed to implement the BIG-PLUS spindle on their machinery. Despite the fact that BIG-PLUS was developed some twenty-five years ago in Japan, the adoption of BIG-PLUS spindles is seeing steady, solid growth across the industry. The full list of big and small names can be found at https://www.bigkaiser.com/en/big-plusr-spindle-system-machine-tool-builders.

Christian Spicher, Head of Sales and Marketing at BIG KAISER, said, "Many of our customers will already have BIG-PLUS compatible machines, and many of their spindles may actually be BIG-PLUS compliant, but they may not be aware of this important fact – which means they are missing out on the substantial benefits provided by this rigid dual-contact interface.”

For customers who are unsure whether they have a BIG-PLUS spindle, the easiest way to check compliance is to place a standard tool into the spindle and see how large the gap between the tool holder flange face and spindle face is. On machines without the BIG-PLUS system, the standard gap for DV50 should be clearly visible, i.e. approx. 3.2mm. With a BIG-PLUS DV50 spindle, the gap is approximately half the size, i.e. ~1.5mm. Naturally, gap sizes vary accordingly for DV40, DV30 configurations, nevertheless, with BIG-PLUS the gap is always visibly smaller compared to alternative spindle interfaces.

DV50BDV50

While competitors offer "dual-contact tool holders” that claim to provide a similar flange and taper contact solution to BIG-PLUS, these holders are not typically made to sufficiently tight tolerances and may not provide a sufficiently rigid contact interface. Using unlicensed tool holders unnecessarily risks connections that are less robust as well as expensive spindle damage, potentially voiding the machine’s warranty.

To help its customers, BIG KAISER has developed a simple test that can easily determine whether a tool holder is in fact a genuine BIG-PLUS spindle or an unlicensed dual-contact tool holder.

If a BIG-PLUS spindle is used with standard V-flange tools, over time this will result in wear on the spindle and alter its geometry. Since a rigid simultaneous taper and face contact is required, geometry is a critical factor, and even minor deviations will impair the BIG-PLUS spindle’s ability to deliver on its full potential.

To address this issue, BIG KAISER offers its customers special spindle and tool taper cleaners, as well as arm alignment tools. However, to restore a BIG-PLUS spindle to its proper specifications, the most effective option is a certified regrind.

The BIG-PLUS system was invented by BIG KAISER’s parent company, BIG Daishowa in 1993. Its time-proven superior vibration damping and rigidity noticeably improve machining accuracy and repeatability and facilitate heavy duty and high-speed cutting, whilst also providing a longer tool life. For example, in shoulder milling tests, when compared with a conventional BT holder, the BIG-PLUS system reduced the deflection of a machine part by 30%.

The BIG-PLUS solution ensures that as the tool enters the machine spindle, the taper makes the initial contact. Due to the pull-in force, the tool taper expands the spindle in the elastic range of the steel. The tool is then pulled farther into the spindle until the tool flange reaches the surface of the spindle nose.

These tool holders are firmly held to a fixed relationship between the gauge line and the face with a tolerance of only a few microns. With such a tight tolerance, BIG KAISER can be sure that any BIG-PLUS tool put into any BIG-PLUS spindle will have the proper taper and face contact. Having the same dimensions as conventional BT or SK holders BIG-PLUS is fully interchangeable with existing accessories.