#Industry News

SPACER COUPLINGS with ComInTec

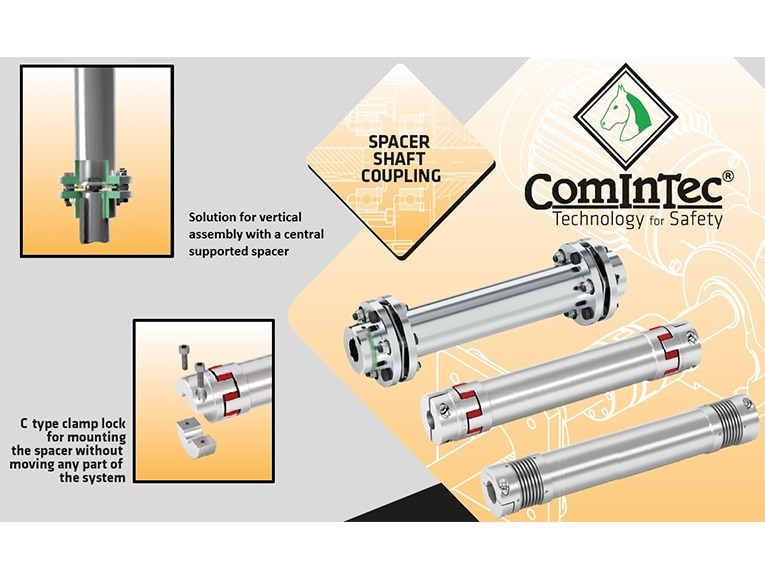

Spacer Shaft Couplings Made to Measure

ComInTec, an Italian company with decades of experience in the production of mechanical components has designed a series of spacer couplings to connect two shafts distant from each other. The spacer coupling can be supplied with various flexible elements, hub connection methods and customised lengths depending on the performance to best suit the specific application.

The spacer couplings connect the shafts of a kinematic chain, with the option to integrate a torque limiter in order to both provide overload protection in addition to connecting the shafts. Different types of machinery such as screw jacks, driving units and actuators can be fitted with this system. ComInTec has developed three models of spacer couplings to facilitate the connection of shafts positioned far apart from each other to accommodate potential large misalignments often present.

Example of the GSF Bellows spacer coupling with torque limiter.

The central spacers are customised, manufactured and assembled to respect a certain D.B.S.E. (Distance Between Shafts End) dictated by the specific application of the customer, with lengths of over 3m possible depending on technical parameters.

AVAILABLE MODELS:

Torsionally rigid spacer coupling with flexible disc pack elements

GTR/DBSE

Elastic spacer coupling with flexible elastomeric elements

GAS/SG/DBSE-AL

Torsionally rigid spacer coupling with flexible bellow element

GSF/DBSE

Every model responds to specific requirements of rigidity, locking system, length and assembly method; all models have common productivity and efficiency goals sought in the most dynamic industrial sectors, system simplification that reduces probable sources of maintenance and superfluous management, simple assembly that reduces machine downtime and optimize the performance/price ratio.

ComInTec’s spacer couplings can be customised with specific lengths and ad hoc locking systems, adequate to the specific characteristics of any industrial plant.

Assembly is fast and simple; with the possibility to avoid axial displacement of the machine’s components using a locking clamp, separable in two parts, with plain bore or keyway.

Assembly is fast and simple; with the possibility to avoid axial displacement of the machine’s components using a locking clamp, separable in two parts, with plain bore or keyway.

Applications of this type of spacer couplings are assembly of actuators, screw jacks, bevel gearboxes/servomechanisms, used to transfer motion between distant components.

Torsionally rigid spacer coupling with flexible disc pack elements

GTR/DBSE

Torsionally rigid coupling made of finished steel, with stainless steel disc packs. The welded steel spacer guarantees retention and consolidation of torsional rigidity. All the components of this spacer coupling are put through standard anticorrosive galvanizing process for external use. Among the main areas of application for this transmission coupling: machines in the textile industry, packaging machinery, lifting systems and test benches. Designed for use at high temperatures in foundries and moulding industries.

This coupling’s characteristics, free of maintenance, and the multiple locking possibilities - clamp, separable in two parts, with plain bore or keyway – make it very versatile for transmission torques up to 130KN.

Elastic spacer coupling with flexible elastomeric elements

GAS/SG/DBSE-AL

Made of fully turned aluminum, ideal to connect driving units due to its low inertia and custom spacer for specific DBSE.

The C type clamp lock allows mounting the spacer without moving any part of the system. The elastomers, made of polyurethane material, are available in various hardness levels, that dampen vibrations and electrically isolate the coupling. The elastomeric elements are particularly resistant to aging, abrasion, fatigue, hydrolysis and to UV radiations, as well as to main chemical agents. Widely used in industrial stirrers and mixers, conveyors and photovoltaic systems.

Torsionally rigid spacer coupling with flexible bellow element

GSF/DBSE

Hubs and spacer made of fully turned aluminum make this couple compatible with high temperatures. The flexible elements - two stainless steel bellows - allow high angular misalignment recovery and low inertia. Characterized by high torsional rigidity it can be combined with security components such as torque limiters. The locking systems for this type of spacer coupling can also be customized using one or two piece clamp hubs, with or without keyway. Mainly used to connect actuators and/or servo motors.

ComInTec: the most complete range of couplings available.