#Product Trends

Hexagon Manufacturing Intelligence Launches New Rotary Tables for Optiv Performance 663/664

Rotary Table and Stacked Rotary Table Options Improve Part Accessibility and Measurement Cycle Efficiency

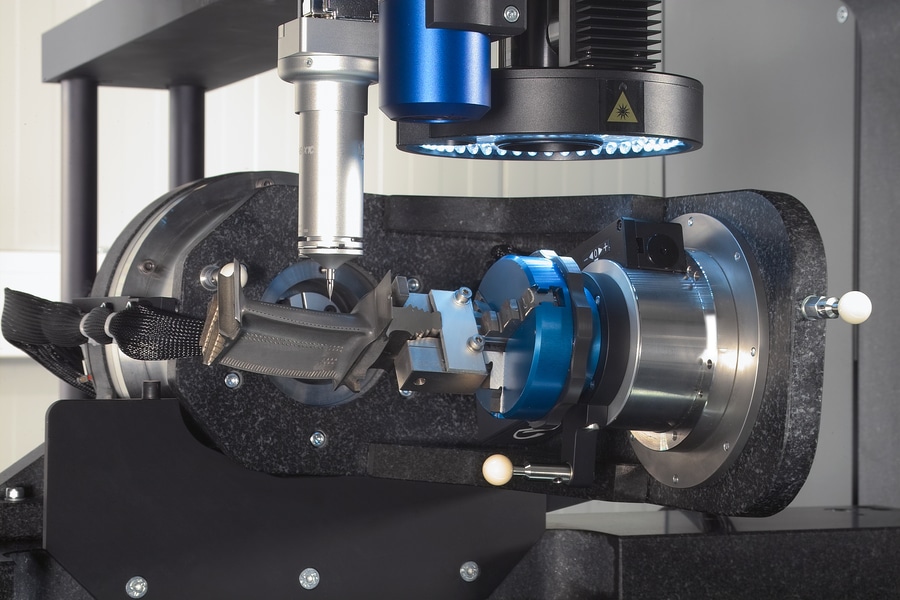

Hexagon Manufacturing Intelligence has extended the accessory range for the Optiv Performance 663 and Optiv Performance 664 coordinate measuring machines (CMMs) by adding two new computer numeric control (CNC) rotary tables and the Optiv Dual Rotary CNC stacked rotary tables as options, substantially widening the application potential of the multisensor machines.

The use of the fully-integrated CNC rotary axis increases the overall inspection performance, especially when measuring rotationally symmetrical parts. Such workpieces can be completely measured in a single setup as features distributed around the circumference of the part can be precisely rotated into a position which is optimal for the multisensor measurement. The PC-DMIS measuring software takes the rotation of the workpiece coordinate system relative to the machine coordinate system into account. The Optiv Dual Rotary option allows the entire rotary axis to swivel on an additional axis so the sensors can reach geometries that are inclined to the longitudinal axis of the workpiece.

The tactile measurement of prismatic workpieces on a rotary table or the stacked rotary tables also offers improved efficiency through the rotating and swivelling movement, which makes complex geometries easily accessible with only a few simple styli configurations. This reduces the necessary probe changes as well as the number of axis movements within the measuring volume.

The new mechanical bearing rotary tables for the Optiv Performance 663/664 provide high-precision rotational accuracy. Two sizes are available, offering different maximum torques (2 Nm or 10 Nm) and normal centred load capacities (900 N or 1800 N). Depending on the version, self-centring three-jaw precision chucks for diameters between 2 mm and 125 mm are optionally available. With the Optiv Dual Rotary option, two rotary tables are combined to enable two-axis rotations.

“We have extended the range of applications for the Optiv Performance 663/664 with the automatic workpiece rotation within one measurement routine,” says Wolfram Fröhlich, Business Unit Director PL sCMM for the Vision Unit at Hexagon Manufacturing Intelligence. “With up to two additional rotary axes, our customers can make optimum use of the available measuring volume of the machine and perform complete multisensor measurements of complex components without re-clamping.”

Both CNC rotary tables and the CNC stacked rotary tables are available worldwide from today and can be ordered from local Hexagon Manufacturing Intelligence commercial operations and dealers.