#Product Trends

Industrial gas springs from ACE made of stainless steel

A brilliant choice in every respect

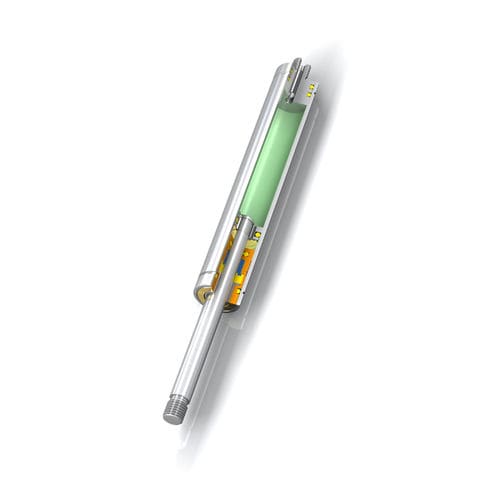

Industrial gas springs are ideal as practical aids when opening and closing hoods, lids and flaps. These small machine elements, which easily and reliably support the user's muscular strength, are available from ACE Stoßsperre GmbH as gas pressure and gas tension springs. Industrial gas spring types in V2A and V4A stainless steel further expand the application options for designers.

Controlled lifting and lowering without great effort and without the risk of pinching your fingers, for example during maintenance work. Coupled with enormous versatility and long service life, these are important advantages of these components, which have proven themselves in many applications. Whether made of steel or stainless steel, industrial gas springs from ACE make work easier and the special designs also look good.

Industrial gas springs or gas springs: a question of space

As standard, ACE industrial gas springs are available with body diameters from 8 to 70 mm and forces from 10 to 13,000 N. As standard industrial gas springs, they are available in formats from 15 to 40 mm and are designed for forces between 30 and 5,000 N. Both versions are filled with pressurized nitrogen gas. With industrial gas springs, the nitrogen flows through the throttle opening in the piston when hoods, lids and flaps are opened and ensures a defined extension speed and a secure hold. In addition, when the maintenance-free, self-contained systems are extended, the oil filling causes them to touch down gently in the end position. For this reason, the end position cushioning is only effective when the industrial gas pressure springs are installed when the piston rod points downwards. When opening, the nitrogen flows back and also supports manual strength. The particularly good adjustability of these damping solutions from ACE can be explained above all by the individual filling of the industrial gas springs with nitrogen thanks to the valve technology used. With their help, the forces can be precisely adapted to the respective application on site with a filling case, depending on the customer's requirements. Further modifications also make it possible to lock industrial gas springs, which enables exact positioning at any point in the stroke. If industrial gas springs cannot be used for reasons of space, industrial gas springs are the method of choice. They are effective in the pulling direction and work according to the reverse functional principle: the piston rod is pulled inwards by the gas pressure in the cylinder and manual force is supported by the pressure spring when closing a flap, for example. ACE industrial gas springs are also self-contained, maintenance-free machine elements and are equipped as standard with a valve for individual regulation of the gas pressure. Whether working in the push or pull direction, ACE offers suitable accessories for every application, which also enable installation in difficult places.

Stainless steel variants expand areas of application

Both industrial gas springs and industrial gas pressure springs from ACE with the type designations GZ-15 to GZ-40 and GS-15 to GS-40 with body diameters of 15 to 40 mm are available in stainless steel alloys V2A and V4A. In addition, industrial gas springs are offered in formats from 8 to 12 mm as types GS-8 to GS-12 in V4A. The technical consultant responsible for industrial gas springs, Patrick Czeckay from ACE, explains the reasons for this: "Our smaller GS types are rarely requested in stainless steel and if so, our customers need the more resistant V4A alloy. Due to their space-saving design, there is no demand for even smaller types of stainless steel for industrial gas springs.” The qualitative difference between the two stainless steels is that the chromium-nickel steel of V4A still contains molybdenum. For this reason, the company from Langenfeld in the Rhineland mainly offers types made of V4A stainless steel for shipbuilding, for example when raising hatches or for a regulated speed when extending dinghies. In contrast to the V2A alloy, this is more resistant to corrosion and seawater due to the molybdenum content. In terms of robustness against environmental influences, all stainless steel gas springs from ACE impress in the long term with full functionality, an attractive appearance and a long service life. High-quality accessories offer customers the opportunity to install them in machines and systems themselves, especially since all connecting parts are DIN standardized and also available in stainless steel. Due to their glossy appearance, they are often used in areas frequented by the public. Otherwise, they are used when the hygiene requirements are even more demanding, such as in medical and clean room technology as well as in the food industry.