#Product Trends

Relief during handling and conversion: universal screwdriver with gas tension spring and structural dampers from ACE

More flexibility and easier work on universal screwdrivers with ACE gas tension springs

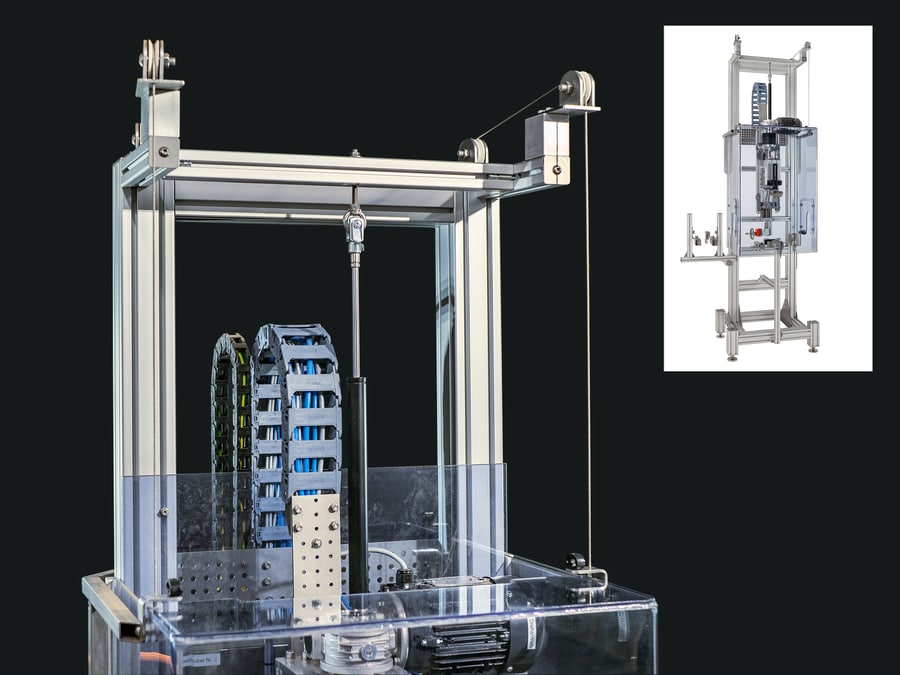

The further development of the universal screwdriver from Metallatelier GmbH presented in part 1 is not only equipped with small shock absorbers, which serve to protect the construction in the end positions and increase productivity, but also with gas tension springs and structural dampers from ACE. These energy-saving and protective components serve to facilitate height adjustment and, in addition to the innovative overall design, are the focus of this second part of the user report.

The universal screwdrivers developed and manufactured for Bilgram Chemie GmbH from Ostrach in Upper Swabia represent a small series. The minds behind the design are David Fuchs, inventor of the utility model-protected predecessor and owner of Metallatelier GmbH, as well as designer Sunyam Riegger and the assembly team from Deggenhausen in Lake Constance. Based on their experience in designing the first series, the further development was primarily about increasing the production speeds of the special machines, increasing flexibility and making handling easier for the operating staff in shift operations. These requirements arose primarily from the fact that since the COVID-19 pandemic, Bilgram Chemie GmbH has had to fill and screw large quantities of bottles of various sizes with disinfectants in a very short time.

Gas tension spring only selected online...

Overall, the higher cycle rates of the universal screwdriver are not only due to the pneumatic drive and the three small shock absorbers from ACE used to brake the vertical movements more quickly. Reducing changeover times plays an additional role when the special machine is set up for different bottle sizes. It was clear to the designers: the biggest limiting factor that could be eliminated when handling the screwing unit for the staff is the weight. Since Metallatelier GmbH had already worked with ACE Schockdampfer GmbH on the first generation of the universal screwdriver as well as on other construction projects, the Langenfeld-based company was also the first point of contact for designer Sunyam Riegger in this case when he was looking for a solution to adjust the height of the screwdriver unit to make it easier: “The experiences with ACE have been very good so far. That’s why we had full confidence that the various components for the extended tasks on the 2020 universal screwdriver would work just as well as the small shock absorbers on its predecessor.”

Since a power-independent solution was preferred for height adjustment and speed regulation of the screwing unit, ACE's industrial gas springs attracted the greatest interest right from the development stage. A particular challenge for integrating these slim components is the compact overall design. For example, the entire substructure is made from Item profile and attached to adjustable feet with an adjustment range of 250 mm. These are connected to the upper part, also made of aluminum profiles, to which the energy chain and the pneumatic drive including a movable carriage from Festo are attached. Because of the limited installation space, the team around David Fuchs and Sunyam Riegger decided after a test design on the ACE homepage www.ace-ace.de/de/berechnungen/schnellsregulation/gasfeder-berechnung-online.html and subsequent discussions with the damping specialists the Rhineland for industrial gas tension springs of the type GZ-28-250-DD-330N.

... and then adjusted manually

In contrast to the better-known industrial gas pressure springs, these variants require less space because the piston rod is pulled inwards. The self-contained, maintenance-free machine elements with body diameters of 15 to 40 mm are able to cover tensile forces between 30 and 5,000 N. Any installation position, comprehensive, DIN-standardized accessories and various designs enable universal use, now for the first time on the universal screwdriver from Metallatelier GmbH. Above all, Sunyam Riegger took advantage of an essential property that ACE gives to these mechanical supporters of human muscle power. It is about the possibility of individually adjusting the gas pressure using a valve: “For fine-tuning after the design of the type, we simulated the settings with a weight that corresponded exactly to that of the screwing unit before the initial installation. We then gradually released just as much nitrogen from the gas spring until the highest level of comfort and the best fixation were achieved.” Only after all the tests had been successfully completed was the precisely adapted gas tension spring integrated into the overall design. The included accessories made integration into the system possible in a very short time.

In daily use in the Bilgram Chemie GmbH plant, the gas tension springs perform reliably and allow the screwing unit to be raised or lowered in a short time and thus precise conversion from small to large bottles and back again, so that production capacities can be optimally utilized.

In addition, components for shock absorption

In order to avoid unnecessary downtime due to damage or even injuries, structural dampers from ACE are installed in addition to the small shock absorbers and gas tension springs. The solid-state dampers serve as shock absorbers at the upper end of the screwdriver's protective hood. The machine elements, named TUBUS because of their shape, are cost-effective alternatives to hydraulic dampers when precise stopping of moving masses is not important: “The three different components that we get from a single source at ACE make our system fast, flexible, safe and stable . “They also helped us, together with Bilgram, to make a small contribution to combating the corona pandemic,” says David Fuchs, summing up the cooperation between the three companies mentioned positively.

Technology box

On the move when things get tight: industrial gas tension springs from ACE

The installed gas tension springs of type GZ-28-250-DD-330N are theoretically able to apply up to 1,200 N of pulling force each with a stroke of 250 mm. However, due to the technical requirements, in this specific case, after delivery, the designers set them to the final value of 330 N in test operation via the valve, which is easily accessible on the outside of the body, in order to be optimally adjusted for the raising and lowering of the screwing unit.

Gas tension springs from ACE are favored by designers when a standard gas pressure spring cannot be used due to space constraints. The gas tension springs work in the opposite way compared to conventional gas pressure springs. The piston rod of gas tension springs is located in the cylinder when unloaded. The gas pressure in the cylinder pulls the piston rod inwards. Gas tension springs from ACE offer very long service lives thanks to hard chrome-plated piston rods and integrated plain bearings, which was another big plus for the designers and end customers of Metallatelier GmbH due to the shift operation.