#Industry News

Latest generation monoblock bridge saw GOLD

Achilli’s experience and technology in a new 4 axes bridge saw with the best price-quality ratio in the market.

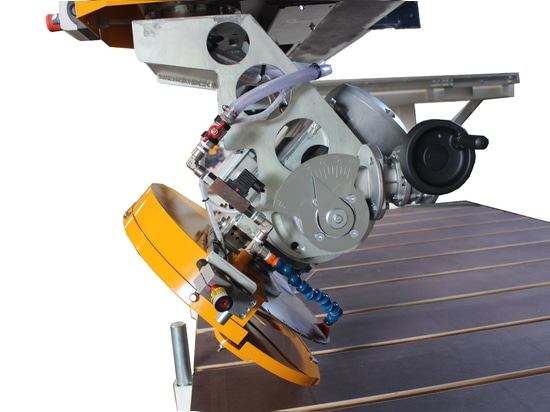

The highest cutting precision is guaranteed by the head motion on linear guides with recirculating ball slides by means of motors equipped with digital inverter. Motorized head travel with variable speed on three axes.

The automatic rotation of the head is available in 2 positions 0 ° -90 °, or complete from 0 ° to 360 ° to perform interpolated diagonal cuts in all directions.

The manual head tilt from 90 to 0 degrees by hand wheel allows the execution of inclined and horizontal cuts. It is possible to mount a core drill with ½” gas connection.

The axes travel is: X = 3500mm Y = 2000mm, Z = 380mm

The steel frame is sturdy and compact, completely sandblasted and ceramic coated; it can be hot dip galvanized treated upon request.

The automatic execution of cutting programs takes place by means of the touch screen CNC control, mounted on the electrical panel or on a movable arm. The control allows also the cuts execution in "manual" mode.

The laser alignment device mounted on the head, permits to achieve an effective cutting optimization, showing the blade cutting line. Furthermore the mobile pendant control unit allows immediate head movement when the operator is working far from the control position.

Depending on customers’ requirements, the worktable, covered with replaceable plywood boards, can be fixed, tilting, with motorized hydraulic tilt in almost vertical position and/or rotating with positive locks at 0° -/+90° -/+45° or free brake positioning.

Achilli bridge saws are totally customizable and available with various options and accessories to accurately meet customers' requirements.