#Industry News

Superlative high-pressure pump

Superlative high-pressure pump.

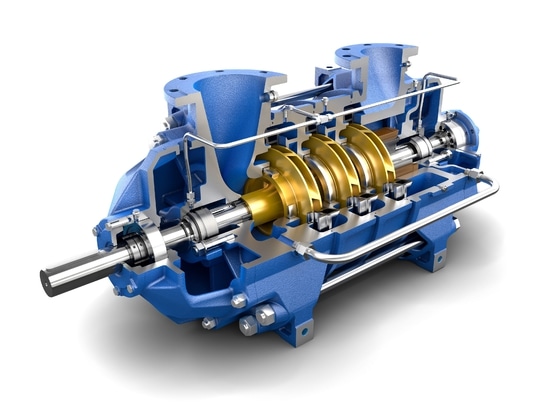

To observers, the new high-pressure pump from ANDRITZ represents a considerable advance in pump technology. With an efficiency of up to 90 percent, the completely redesigned series is the premium class of the pump manufacturer. Behind this lies more than 100 years of product experience, a global technology network, use of the latest simulation and test equipment and several years of development time. A clear goal was pursued: The construction of the most efficient high-pressure pump.

"From the very start the orientation of the upper limit of what is technically feasible was the key focus of the project", stated the head of the International development team, Jan Silberbach. With engineers from different locations of the international technology group we succeeded in something that is regarded with pride as the "step towards superlatives".

The modular machine can be incrementally expanded as needed. It is available in both horizontal and vertical versions. Suction and discharge nozzles can be variably arranged depending on application. With nominal sizes from 40 to 200 millimetres, the pump reaches flow rates of up to 850 cubic meters per hour at up to 40 bar delivery pressure in the first stage. In the second stage 63 bar can be achieved.

In the future Andritz will offer the premium class high-pressure pumps both in ductile cast iron as well as in high-alloy stainless steel. The bearing of the pump shaft, depending on the design selected, is through grease lubricated bearings or via conveyed medium lubricated plain bearings.

With regards to the shaft seal, various options are available. Depending on the delivery pressure, the pump is standard run with balanced or unbalanced mechanical seal. Optionally, a cartridge seal or gland packing is available.

In order to guarantee the longest possible service life of the pump's wearing parts protective sleeves, thrust and split rings in top quality materials are used.

Thanks to its unique high efficiency, the pump is also ecologically sound. A fact which represents considerable savings for the user during energy transition. The design which is clearly geared towards energy efficiency can honestly be described as a "green pump". Calculated in Euro and cents, this means significant financial savings in energy costs, meaning the pump would pay for itself within a short period of time.

The Andritz engineers can move confidently towards the future with the experience gained from the development of the new high-pressure pump. "The development continues!" promises the Head of Development Olaf Nowack and says: "There is no such thing as a product that can't be improved upon."

Today the new series has already not only overtaken the previous generation in terms of robustness and efficiency, but has left it far behind.