#Product Trends

Introduction of the pipe brush application range

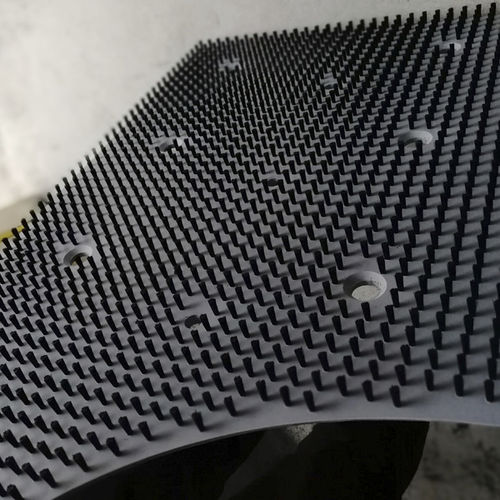

Pipeline Cleaning Brush

We would like to talk something about the pipe brush and wire tube brush here, the pipe brush mainly used for removing tiny burrs on the surface of the hole after finishing, thereby improving the smoothness of the inner hole, generally increasing from a small to a large level.

The major materials used for production of pipe brush are including nylon wire, fiber wool, pig bristle, steel wire, copper wire, abrasive wire, etc., it can be varied for different application ranges.

These years the demand on pipe brush have been increasing, as its application range is very wide, which can be used in hydraulic cutting hole groove deburring, cross hole deburring, air conditioning refrigerator (compressor) deburring, cylinder deburring, engine zero Accessories, machining, in-hole machining, brake boring; and the pipe brush is very suitable for the polishing of some round, cone, and venturi holes.

The spherical wire brush can quickly and easily do the job of surface treatment on cylinders, valves, lumens and it can be applied for the various shapes and sizes of pipe. The polishing pipe brush can be self-centering, and the pipe brush can automatically calibrate, all the processes will be in a fine and consistent manner without affecting the precision and scale of the workpiece. Generally, it is convenient, safe, economical and effective.

Pipe brushes are widely used no matter in heavy industry but also in medical field, which can be used for cleaning different types of pipes. As the pipe brush can not only clean the surface of the pipe but also the bottom of the pipe, even if it’s deep enough, the

They can clean both sides and top of the pipe, even if it is deep, the latest pipe brush produced by Waldo can do the cleaning job perfectly.