#Industry News

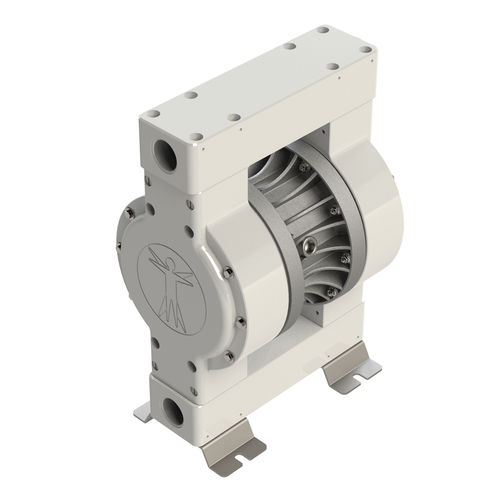

AODD pumps for filter press

ARGALAIR series are the perfect solutions

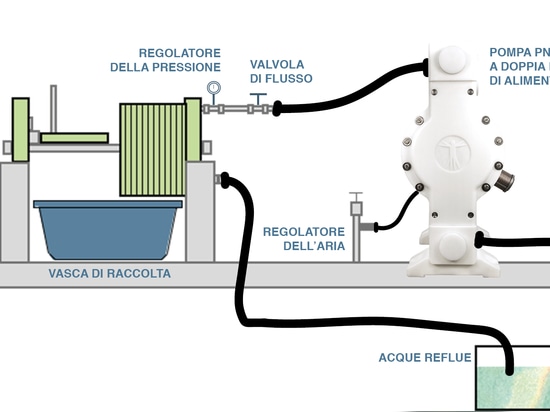

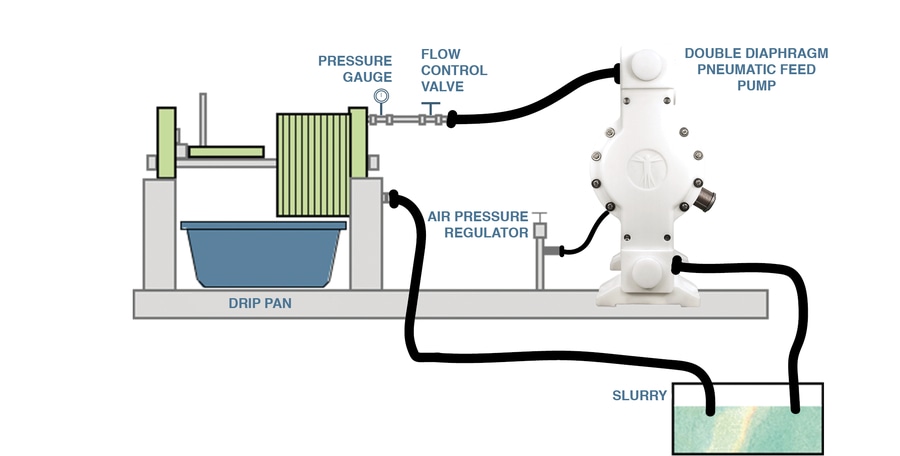

How does a filter press system work?

It mechanically separates the liquid from the solid sludges/slurries/sewages. The filter press consists of metallic plates coated covered with paper, felt medium or synthetic woven material and these plates are supported by a mechanical structure. A closure mechanism keeps sealed the plates’ faces to counteract the force of filtration (squeezing): this reduces the liquid content in the waste slurry or the solid contents in the industrial processes.

Why ARGALAIR pneumatic pumps are the ideal solutions for this process?

- They reach pressure up to 20 bar

- Low maintenance cost thanks to their few components (especially if compared to mechanical seals or packing costs)

- Simple and compact design

- The pulsating flow produces pressure peaks that keep constantly cleaned the filter screens

- Flow and pressure continuously change during the filtration process and the ARGALAIR AODD pumps are extremely versatile and able to adapt to the changing working parameters.

- ARGALAIR AODD pumps are self-priming and can run dry: a perfect solution when the filter press is blocked (often) due to the viscosities of the liquid being pumped