#Product Trends

3 Benefits Of Stainless-Steel TV Enclosures In Food Processing

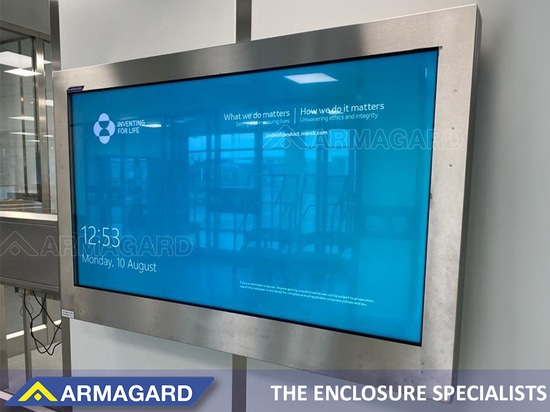

Improve productivity and hygiene with stainless-steel TV enclosures.

Boost productivity, improve hygiene and enjoy a low total cost of ownership. Stainless-steel TV enclosures let you install digital screens in locations that require washing down.

You can get enclosures with IP54, IP65 and IP69K ratings. That means you can jet wash your shop-floor TVs quickly and safely. The 316 stainless-steel construction is corrosion resistant and antibacterial, which helps you meet food safety standards.

Read on to discover how stainless-steel display enclosures can improve communication, output and hygiene in your food plant.

1. Improve Shop Floor Communication And Productivity

Large-format displays make KPIs and other information visible to everyone on your shop floor. Staff benefit from real-time updates that help them hit quotas.

You can get stainless-steel TV enclosures for screens from 32" to 86". These units are bigger than traditional HMI touch screens, so you don't have to choose between what you show. Divide the display to show different information at the same time, such as safety info, company updates, and shift targets. KPIs stay clear on half of the screen while other information circulates on the rest.

Versatile mounting lets you boost visibility across your production line. You can hang enclosures from a ceiling or install them flat or tilted on a wall or column.

Armagard's hygienic production displays work reliably 24/7. That means each shift gets the information it needs to maximise productivity at any time of day or night. The enclosures' design lets you leave them on during daily wash down cleaning, for maximum uptime, output and return-on-investment (ROI).

2. Easily Meet Hygiene Standards

Food factory stainless-steel TVs help you maintain hygiene in three important ways:

316 Stainless Steel:

Armagard enclosures are made from food-grade (316) stainless steel. This is antibacterial, corrosion resistant and easy to clean. Lower grades of steel, like 304, might look identical, but they're likely to degrade under frequent washing down. This can lead to bacteria build-up and poor hygiene.

316 stainless, on the other hand, contains 2—3% molybdenum. This increases corrosion resistance, making it ideal for food processing TV enclosures. Extra corrosion resistance also increases the lifespan of 316 compared to 304. This makes 316 more cost-effective, as it provides greater equipment longevity in wet locations.

IP Ratings:

Armagard's stainless-steel LCD enclosures are industry rated to IP54, IP65 or IP69K. You can carry out easy cleaning with high-pressure, high temperature jets — with no risk to the enclosed screen.

You benefit from quick washdowns that clean your enclosures of food debris and particulate build-up. Fast cleaning also means less disruption to your production schedule.

Shatterproof Polycarbonate:

Armagard's food manufacturing digital signage cabinets have shatterproof polycarbonate windows. These are 20x stronger than glass and won't shatter into tiny pieces in the unlikely event of a breakage. This protects your production line from contamination, preventing lost product and manufacturing shutdown.

Stainless-steel TV enclosures give you peace of mind about hygiene standards. This goes beyond meeting the formal regulations. You want to avoid the nightmare of recalling products, and any contamination traced back to your plant will have a huge impact on reputation.

That's why 316 stainless-steel enclosures are a great choice — they give you confidence in the hygiene and reputation of your plant for the long term.

3. Enjoy A Low Total Cost Of Ownership

Stainless-steel display enclosures are a long-term investment that give you ease of use and a low cost of ownership.

An LCD enclosure and TV combination is a user-friendly alternative to an all-in-one, waterproof screen. Install the VESA-ready TV of your choice. Easy access lets you remove, repair and replace the screen at any time. You get quick and easy screen upgrades without needing a specialist engineer.

Armagard's food processing enclosures come with a five-year warranty and an expected 10-year lifespan. This makes them highly cost-effective, as you can use a single enclosure to protect successive screens over several years.

Custom options mean you get an enclosure that meets the needs of your plant for the long term. Choose the best size, IP rating and climate controls for your manufacturing floor.