#Industry News

AEROSPACE REPORT

Precision flies

The aeronautical and aerospace sector has

in AZ SpA a technological partner able to

propose numerous specific grinding

solutions with high innovative content. In the

range of grinders designed by AZ, the new

LBC777 line for the orbital machining

of landing gear is a recent and very

successful example.

The aerospace sector is in continuous

technological evolution and seems not to

know crisis. Direct, indirect EOM and

certified aerospace subcontractors always

research and develop innovations for all

components and processing processes

used, for example, new "hyper-special"

materials such as inconel, high-alloy steels,

super alloys with base of cobalt and nickel,

titanium etc. Aerospace also means working

on very expensive single pieces and

following strict production procedures with

special work cycles that guarantee their

traceability and above all "zero defect" on

the final pieces. For machine tool suppliers,

and in particular for finishing machines

such as grinding machines, no mistakes

are allowed.

In this context, among the manufacturers

of cylindrical grinding machines accredited

for aerospace, the Italian AZ SpA of Thiene

(VI) has been able to gain a worldwide

leadership success thanks to the high quality

and performance levels of its products. This

is the result of high professionalism and

engineering creativity able to grasp and

often anticipate market demands. AZ has an

impressive range of grinding solutions

designed specifically for the aerospace

industry called "AZ Aerospace" for the

manufacture and maintenance of

components of aircraft engines and

landing gear.

AZ grinding machines are all

customisable, energy efficient, safe, reliable

and comply with Industry 4.0 requirements.

The numerous lines available are developed

with the range AKP for landing gear

grinding machines with gap bed, GSB for

internal landing gear grinding machines, RU

and RUG for universal grinding machines for

external and internal diameters and LBC for

landing gear orbital grinding machines for

external and internal diameters.

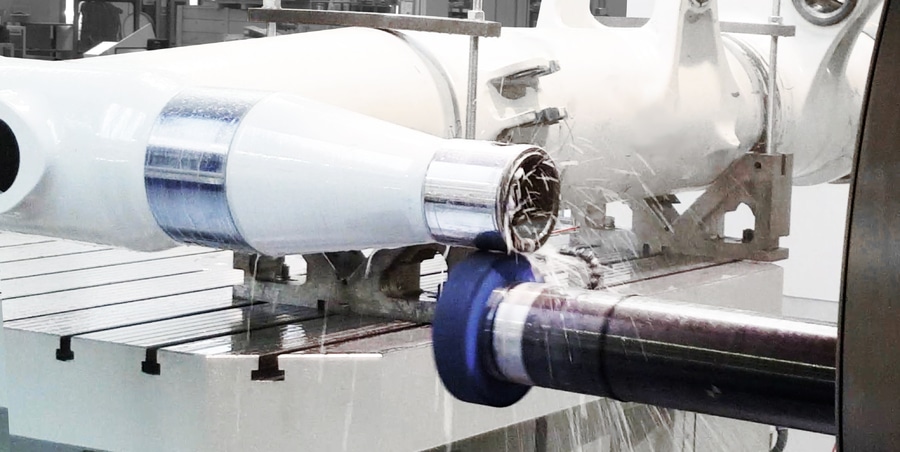

In particular, the new LBC777 represents a

recent example of a solution for

asymmetrical heavy parts with rotating

table. One of these grinding centres is

successfully used for all Boeing series with

others for alternative brands of landing

gear. A new self-balancing orbital grinding

system and rotary table facilitates the

grinding of the heavy-duty landing gears

without displacement of the workpiece. In

fact, the rotary table allows the grinding of

external and internal diameters in a single

piece grip and is moved by the overlapped

and crossed arrangement of the main

machining axes, Z and X, which allows ample

operating capacity with reduced dimensions

on the ground. The machine axes slide on

high precision recirculating linear guides.

The machine base has been designed with

FEM analysis and is made with a special

“Composital” technology structure that

reduces the elasticity coefficient,

guaranteeing an exceptional absorption of

vibrations, great machine rigidity, stiffness

and high dynamic performance.

The LBC777 wheelhead is configured with

two spindles for internal grinding and one

spindle for external grinding. The

wheelhead, mounted on a rigid structure, is

equipped with an AZ system for

self-balancing and runs vertically in the

Y-axis, on sliding guides with anti-friction

material "Turcite" equipped with

automatic lubrication.

The grinding machine is characterised by

the particular processing cycle that takes

place through the orbital grinding of the

workpiece surface. On the stationary piece

and positioned by the rotating table, the

grinding wheel used follows the geometric

trajectory of the piece along its generating

line both for grinding external and internal

diameters. With this axis scheme, the

machine allows an internal grinding capacity

from 70 up to 900 mm, an external grinding

capacity from 10 up to 450 mm and a

tangential grinding capacity of 2,000 x 850

x 1,500 mm.

Silicon carbide, corundum, CBN and

diamond grinding wheels allow grinding all

aerospace materials, metals and their alloys

including chromium and, in particular, those

subjected to the most innovative systems for

thermal spray techniques, such us H.V.O.F.

(High Velocity Oxygen Fuel). The grinding

process has some functions to give to the

operator few automatic and safe working

cycle: electronically variable spindle speed,

GAP control, dressing control, CRASH

control and control of orbital diameters

from CNC. This offers the machine the

possibility to reach unbelievable

performance on accuracy. In addition,

Wikicam is a monitoring system that allows

to control remotely some parameters of the

CNC machine. There is also a built-in live

video streaming solution to monitor what

the machine is doing in real-time. The

connection to the builder's headquarters is

made by a high-strength secure encryption

algorithm, using a VPN.

The grinding machines produced by AZ

use the most advanced mechatronic

solutions. Measurement systems, motors,

drives, as well as machine mechanisms and

applied CNCs, are selected among the best

brands in the world. With over 40 years of

experience in the sector and more than

3,000 grinding machines delivered and

operational in more than 80 countries

worldwide, AZ has always distinguished

itself in tackling and solving technical issues,

even with complex shape, proposing

customised solutions to individual customer

needs. The design creativity of AZ allows the

creation of product lines, like the new

LBC777, to be among the most

sophisticated on the market today.