#Industry News

RUX1800 CNC Universal Grinder for pneumatic hammers

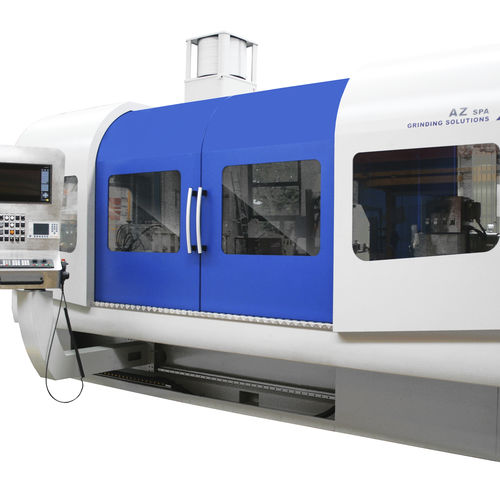

AZ Universal Grinders

RUX is an universal grinding machine CNC controlled. The machine is designed with grinding wheel moves on base by ball screw system and linear guideways. The workpiece is clamped by headstock fixed on the base and tailstock moves easily on the table. Base is specifically designed to obtain the best result between structural deformations and vibration dumping. As optional the table can swivel CNC or manually controlled. The headstock is designed to use different clamping systems in accordance with the specific workpiece. The headstock can swivel manually or automatically. Headstock and tailstock use morse cone or asa centering system. The tailstock is equipped with conicity (taper) adjustement with continuous control of the force between centers. The machine can be equipped with different workpiece supports that can be moved manually or automatically along the table:

• 2 points manual steady rest for external grinding

• 3 points automatic steady rests for external grinding

• 3 points steady rests for internal grinding

• Loading and Unloading V support steady rests

Grinding wheel carriage moves on Z and X axes

by ballscrew and guideways. The grinding wheel

head position is controlled by closed loop linear

encoder rotation. The wheelhead can have different

configurations:

• fixed

• manually B-axis rotation ± 20°

• automatically B-axis rotation ± 30°

The grinding wheel can be equipped with automatic balancing system and vibration control. The grinding wheel dressing is made by automatic fixed point

dresser mounted on the back of the headstock. As optional for ID grinding the machine can be equipped with hydraulic vertical engagement spindle, a rapid

changing system from OD to ID grinding. The machine is equipped with MODULAR MULTI-FUNCTION SYSTEM FOR GRINDING PROCESS CONTROL *

this system can be configured according to customer requests:

• grinding wheel/workpiece contact control

• grinding wheel/diamond contact control and tool usury recovery system

• crash control

• wheel balancing control with automatic balancing device

• workpiece positioning control with touch probe in-process diameter control with 2 points measurement

• digital in process journal size gauge with measuring fork manual engagement

• automatic modular gauge heads for in-process dimensional control