#Industry News

Advantages of high-precision magnetic measurement systems in robotics

Magnetic measurement systems stand out from optical and inductive alternatives due to their unique advantages.

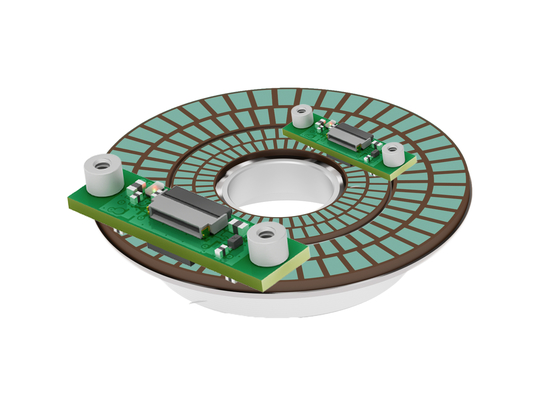

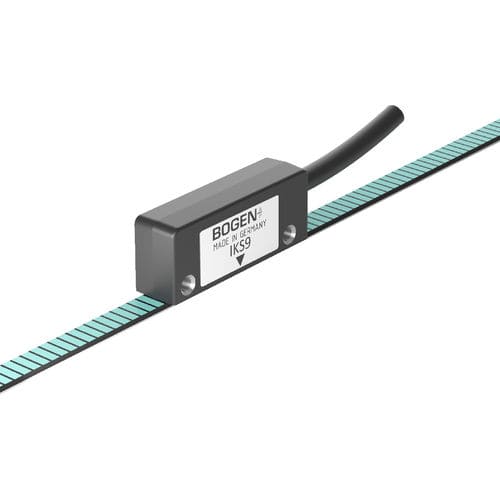

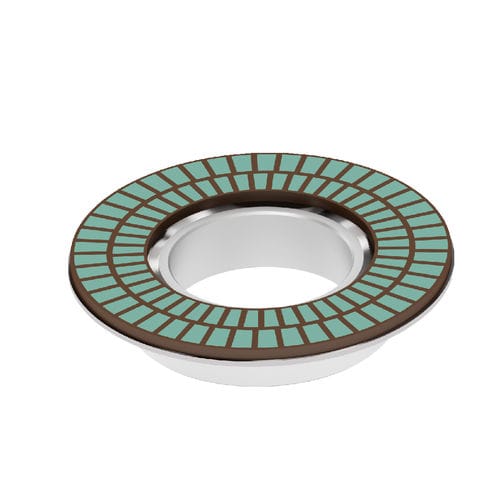

In modern robotics, precision, reliability, and durability are critical for performance. Magnetic measurement systems stand out from optical and inductive alternatives due to their unique advantages.

Advantages of high-precision magnetic measurement systems in robotics compared to optical or inductive solutions

1. Superior durability and resistance to harsh environments

- Magnetic sensors are unaffected by dust, dirt, and oil, making them ideal for industrial automation, where contaminants can degrade optical and inductive sensors.

- No need for optical line-of-sight - magnetic sensors work even in enclosed or embedded applications, ensuring consistent performance.

- Immune to humidity and temperature fluctuations, whereas optical sensors can suffer from condensation, and inductive sensors may drift due to temperature changes.

2. Higher precision with compact designs

- Magnetic linear and rotary measurement systems offer sub-micron precision, competing with high-end optical encoders but without the fragility.

- Compact and lightweight, they integrate seamlessly into robotic joints, grippers, and linear drives without adding bulk.

- No mechanical wear since magnetic sensors operate without direct contact, ensuring long-term accuracy.

3. Greater reliability in dynamic applications

- Unlike inductive sensors, which require proximity to metal surfaces, magnetic sensors work with flexible mounting and larger air gaps, simplifying integration.

- Optical encoders struggle in high-speed, high-vibration environments, whereas magnetic sensors maintain stable readings even under extreme motion.

4. Cost-effective and maintenance-free

- Lower total cost of ownership - magnetic sensors require no cleaning or recalibration, unlike optical systems that need regular maintenance.

- Longer lifespan due to resistance to mechanical wear and environmental factors, reducing downtime and replacement costs.

For engineers and automation specialists looking for high precision, reliability, and cost efficiency, magnetic measurement systems are the superior choice. Whether in robotic arms, grippers, or linear drives, they ensure seamless operation, minimal maintenance, and long-term stability - outperforming optical and inductive alternatives in every key metric.