#Product Trends

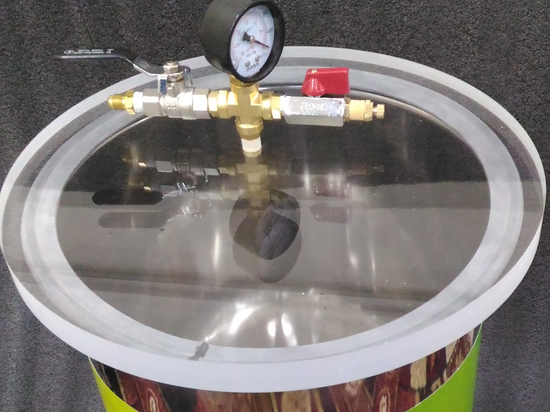

degassing vacuum chamber

degassing vacuum chamber

A vacuum degassing chamber is a crucial tool in various industries, ranging from manufacturing and metallurgy to research and development. It plays a significant role in ensuring the quality, purity, and performance of materials by removing unwanted gases and impurities. This comprehensive guide will delve into the principles, applications, benefits, and considerations associated with vacuum degassing chambers.

In the world of material processing, purity is paramount. Whether it's in metallurgy, electronics manufacturing, or culinary arts, removing unwanted gases and bubbles from substances can make all the difference in achieving superior results. Vacuum degassing chambers, designed to eliminate entrapped gases in liquids and materials, have become indispensable tools across a diverse range of industries. In this comprehensive guide, we will delve into the world of vacuum degassing chambers, exploring their applications, construction, and the vital role they play in delivering pure, high-quality outcomes in various fields.

What is a vacuum degassing chamber?

Vacuum degassing chamber manufactured by Burhani Engineering Technology is a vacuum system comprising of Vacuum chamber and vacuum pump that pulls 29 inches of mercury is used to remove the air from high viscosity materials like epoxy resin, Liquid silicone rubber, liquid plastic and Polyurethane rubber to make bubble free casting. Burhani Engineering Technology is the only exporter and manufacturer of resin vacuum degasser chamber in India for degassing silicone.

The Essence of Vacuum Degassing

Before we plunge into the intricacies of vacuum degassing chambers, let's first understand the fundamental principle