#Industry News

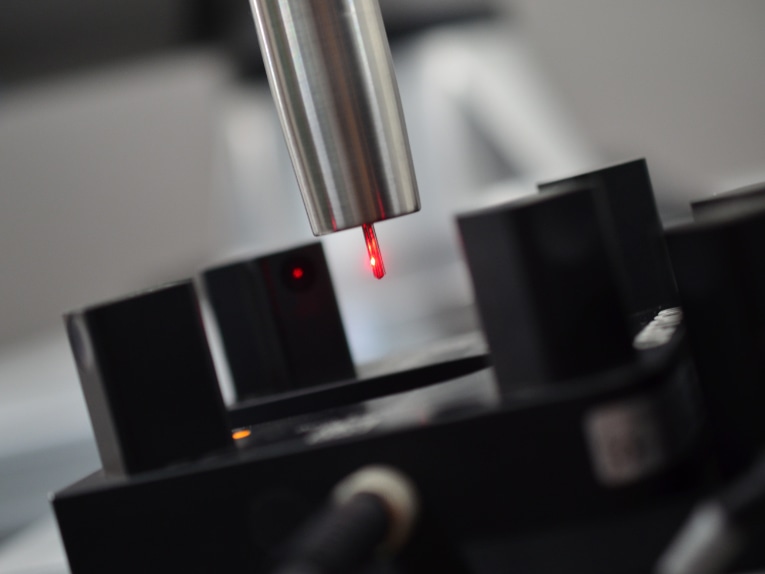

Automatic calibration of TCP's

Revolutionary precision in robotics

In industry, efficiency and precision are paramount. The calibration of the tool center point (TCP) plays a decisive role, especially in robot applications such as dispensing or welding, where maximum accuracy is required. The TCP, i.e. the tool tip, is subject to wear and deformation during operation, which makes regular checks and recalibrations necessary. Ideally, this is done automatically in order to minimize downtimes, reduce rejects and increase product quality.

Advantages of automatic recalibration:

Minimization of downtimes

An automatic inspection and calibration process significantly reduces production interruptions. Instead of interrupting operation for manual readjustments, the check is carried out in a matter of seconds, which leads to a significant increase in productivity.

Increased accuracy and quality

Regular and automatic calibration of the TCP ensures that robot applications are always carried out with the highest precision. This is particularly important for complex tasks such as welding or gluing, as even the slightest deviations can lead to significant quality defects.

Reduction of rejects and rework:

Accurate calibration minimizes errors, collisions and deviations in the production process. This leads to fewer rejects and rework, which in turn reduces costs and increases efficiency.

Reliable tool change:

After each tool change, the robot can run through a quick calibration routine to ensure that the new tool has been inserted correctly and precisely. This ensures continuous and precise production without delays.

Unrivaled speed:

It only takes a few seconds to automatically check whether the current TCP is within tolerance. This fast recalibration eliminates time-consuming manual re-teaching and significantly increases operational efficiency.

The UR+ ecosystem and CAPTRON TCP measurement technology

As a UR+ partner, we have developed TCP measurement technology that is specially optimized for use with UR robots. A URCap was developed to integrate the hardware, which automates the monitoring and correction of the TCP. This solution has been tested and certified by Universal Robots (UR), which guarantees reliability and efficiency.

The URCap in use

The URCap includes an installation page for tool calibrations with a step-by-step setup for up to ten different TCPs. The measurement of the X-Y-Z reference values and the diameter of the tool tip is precise and efficient. Automatic TCP recalibration can be started manually by the operator via the installation page if necessary. A program node enables the automatic checking and recalibration of a TCP during a running program. Limit values and speeds can be defined individually. This program node can be used to check, validate or recalibrate the TCP, with or without adjusting the orientation of the robot arm.

Applications of the URCap

The URCap is versatile and is suitable for the following applications, among others:

- Dispensing, gluing, pipetting

- welding

- soldering

- drilling

- milling

This solution offers considerable advantages, especially for welding applications:

- Minimization of downtimes

- Increased accuracy and quality

- Reduction of rejects and rework

- Reliable tool change

- unprecedented speed

The automatic calibration of Tool Center Points is revolutionizing robotics in the industry. By integrating our TCP measurement technology and UR robots, companies can significantly increase their efficiency and precision. This makes automatic calibration an indispensable best practice.