#Product Trends

Robotic Kits for “Do-It-Yourself” Packaging System Design

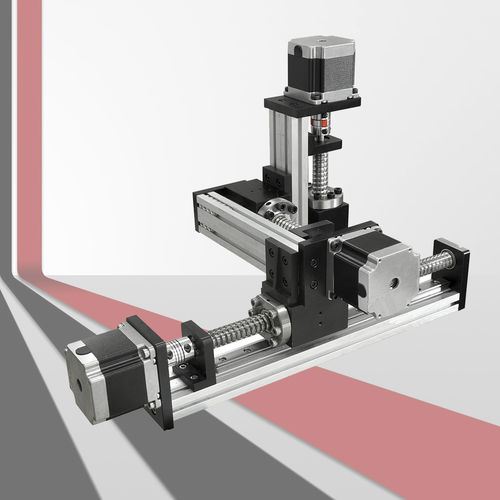

Modular programming and articulating arm kits let you design your own robotic-based packaging system.

For many years two factors gave robot designers and manufacturers a lock on developing equipment for the packaging market: patents and the specialized kinematic knowledge required to program robotic motion. While the robotic arms were under patent, the controls held the unique motion algorithms needed to handle the complex path planning, blending, and resolution of multiple trajectories to the same point. Thus, robot articulating arms and specific controls were exclusive to robot developers.

Conditions have changed, however. The patent on the 3-axis delta robots – those recognizable ‘spider’ arms typically mounted over a workspace and used for pick-and-place with light objects – has expired. The 3-axis delta robots and the two-axis versions are used in both primary (product pick-and-place) and secondary (cartoning and case packing) packaging systems. Now, these arms are available as ‘kits’ for those who wish to outsource or design their own.

As for the controls, no longer are robotic control systems exclusive to robotic manufacturers. Open architecture systems not only replace robot controllers, they also replace the packaging machine’s controller and the PLC as well.

It is not “plug-n-play” simple yet to take these “do-if-yourself” kits and create your own robotic system. Therefore, here are a few tips to ease the process of creating your own robot-based

packaging system.

Application considerations. Articulated robotic systems traditionally suit case packing and palletizing, with smaller versions handling carton erection, filling, and sealing. Gantry and portal systems are typically used for traditional palletizing and for handling heavy payloads and lower speeds.

The first step to ensure that a robot offers the necessary freedom of movement required for these actions is to select the right arm for the job. The 3-axis delta handles high speeds and light loads, a category expected to increase as the concept entered the public domain in Europe a year ago and the U.S. in late 2007. The 2-axis delta handles heavier payloads, offers deeper reach into cases, and collating. It is a popular arm for the current trend of applying robotics in secondary packaging. However, both versions may require additional servo axes to perform their functions.

Motion control considerations. The advanced mathematical algorithms ensure smooth coordination of a robot arm’s multiple joints, wrist actions, and linear travel. While some simple gantries use point-to-point positioning, the real efficiencies come when motions are fluid, fast, and focused on the tool center point (TCP). It is this point that differentiates machine design and robotic motion design.

In robots, motions relate to the TCP rather than to individual axes. Motions are defined by the target position and type of movement of the robot arm through a set of trajectories for each servo axis. The trajectories are individually calculated and synchronized by a virtual camshaft. The various mechanical components operate in unison and can be adjusted dynamically.

The controller calculates the required trajectories for each motor at runtime, enabling the tool path to be easily changed at that time.

Different degrees of freedom are possible, depending on the control software and the manipulator within a given envelope or workspace. Cartesian movements are inherent to the control system. Both the motion and mechanics are flexible.

Commercially available development tools. Motion control toolkits have been introduced in the past three years to overcome the need for the specialized kinematic skills. The kits offer robotics libraries that you can use to program cartesian motion just as you would for a conventional machine into an IEC 61131-3 Function Block. The application of a transformation Function Block then performs all the necessary kinematics.

When all the machine functions are embedded in Function Blocks, it is possible to develop programs in a modular structure, which improves diagnostics, reusability, and response to inputs.

Robotic systems can then be designed as modules linked together through concatenated Function Blocks to perform the transformation (also know as “trafo”) necessary. For example, for a familiar 6-axis articulated robot, plus a trafo for the wrist movement and a trafo for the end-of-arm tool actuation.

As an ARC report recently stated, “Machine modularity allows machine builders to configure a packaging machine based on functional subsystems such as bottle carousels, labelers and wrappers. Integration of a robotic manipulator further leverages the concept of modularity…”

What to look for in development kits. Robots are capable of developing some G forces, and too much can overcome the gripper’s holding force on the product. Therefore, look for intelligent acceleration monitoring to limit accelerations and velocities and contain the resulting centrifugal forces.

The motion commands should include point-to-point, linear or circular interpolation, and splines. Spline curve algorithms map a continuous path between start and target points. Look for a geometric blending capability to reduce cycle times by ‘blending’ the path to optimize speed and distance traveled to reach the target point. You should be allowed to define your criteria for target point, velocity, acceleration, and jerk.

The program should keep both forward and backward movements on the same path – and this is harder than it might first appear, like backing up in your car at 60 mph. Likewise, it should stay on path during an E-stop.

The program should also be able to precisely trigger peripheral motions, such as indexers, wrappers and sealing mechanisms.

Other considerations. It is simpler and the response time faster to integrate robotics with packaging machine operations when control is centralized in a single controller. However, the controller must then be powerful enough to manage one or more robot arms plus all related functions, such as belt tracking and vision systems.

Many controls vendors today claim robotic control among their bag of tricks. But several features can vary greatly, including: ease of development, ease of operation, integration with the rest of the packaging machine, and the response time to adjust an ongoing motion, such as changing belt velocity and just plain speed. Thorough testing will illuminate the differences among suppliers.