#Product Trends

Linear Motor vs. Ball Screw

The Cost-efficient Application for Your Own Design.

While ironless linear motors have been used in semiconductor and electronic applications for more than a decade, they are still viewed by many designers and OEMs as “niche” products. But the perception of linear motors as a costly solution for unique applications is slowly changing, as more industries are adopting them as replacements for ball screws in packaging, assembly, and part loading applications. And while the cost of linear motor technology has dropped over the past decade, the choice between a linear motor and a ball screw must take into account both the application’s performance requirements and the total cost of ownership over the life of the machine or system. Below are some of the key parameters to consider when comparing and choosing between ball screws and linear motors.

Where Linear Motors Excel

A linear motor is essentially an “unrolled” servo motor, where the rotor with permanent magnets becomes the stationary part (also called the secondary), and the stator becomes the moving part (also called the primary, or forcer), with coils encapsulated by epoxy. The most recognized advantage of linear motors is the absence of moving parts, which enables them to achieve much higher positioning accuracy and repeatability than ball screws. Another benefit in positioning accuracy is provided by the encoder. While ball screws typically use a rotary encoder mounted to the motor for positioning feedback, linear motors use a magnetic or optical linear scale for position feedback. The linear scale measures position at the load, which gives a more accurate reading of the actual position. For very high-precision applications, this more accurate position feedback can mean the difference between a part that meets specification and one that requires rework or scrap.

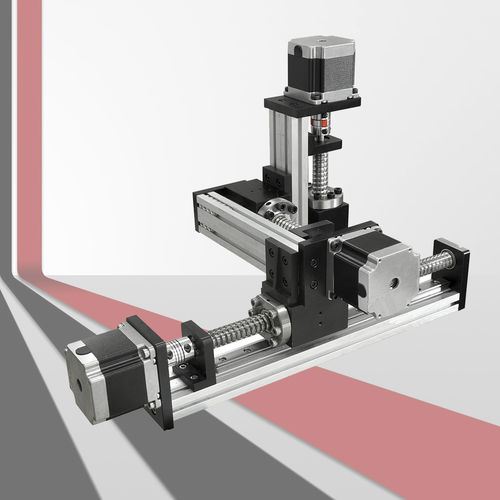

Rotary Linear Motor

In a previous article, we discussed the tradeoff between speed and travel distance in ball screw applications. This is another area where linear motors provide an advantage. The allowable travel length of linear motors is theoretically unlimited, with other components of the system – linear bearings, cable management, and encoders – dictating the maximum travel. Similarly, the maximum speed and acceleration of linear motors are much higher than that of ball screws, with typical ratings up to 10 m/s velocity and 10 g acceleration, as long as other system components are sized correctly to meet these specifications. Despite the limits imposed by other components of the system, linear motors still outperform ball screws in applications that require both long travel length and high speed. They also have the advantage of allowing independently driven carriages (primaries) on the same secondary part. This is especially useful in some packaging applications, where the material to be packaged needs to be compressed before inserting it into the packaging medium (think of diapers packaged inside a poly bag).

Total Cost of Ownership Factors

Maintenance and reliability are important criteria in the total cost of ownership analysis, and linear motors offer several benefits over the life of the system. First, because they contain no mechanical moving parts, linear motors themselves don’t require maintenance. Only the linear support bearings require periodic lubrication, and many bearings are now offered with “long-term” lubrication or “lubed for life” options. The absence of moving parts in the drive system also improves reliability, as there are no rolling elements, bearing raceways or seals that will wear and require replacement over time.

With any linear system, it is important to consider the environment and the need for seals and protective covers. Linear motors are no exception, as they can be more difficult to enclose and protect than traditional ball screw assemblies. In many cases, however, as long as the linear bearings are properly sealed for the working environment, linear motors can withstand more aggressive contamination than ball screws.

For linear motors, the more critical environmental factor is temperature. Because the epoxy used to encapsulate the coils in an ironless linear motor does not readily dissipate heat, cooling may be required – either via forced air or water – to maintain an acceptable operating temperature for both the motor and the mounting structure. Some manufacturers use epoxies with high heat dissipation capabilities, but it is important to check the motor’s thermal dissipation and the effect that temperature will have on the motor’s available force.

More industries and applications are demanding long travel lengths, high speeds, and high positioning accuracy. While many types of linear systems can meet two of these three criteria, linear motors are the only technology that can provide all three without compromise. As throughput and total cost of ownership become the deciding factors in technology selection, designers and OEMs are becoming more familiar with linear motor technologies and helping them move from “niche” to mainstream status, alongside belts, rack and pinions, and even ball screws.