#Industry News

Application Case of Flash Measuring Machine: Connector Size Measurement

The primary measurements include various lengths, widths, and the spacing between pins.

Concept

Connectors, also known as interconnects, plugs, and sockets, are crucial components in electronic products for the transmission of current, voltage, and various switch quantities. In today’s era of diversified electronic product functions and modular design, connectors are increasingly significant, necessitating strict requirements for their contour dimensions.

Inspection Requirements

The primary measurements include various lengths, widths, and the spacing between pins.

Inspection Challenges

As the electronics industry rapidly advances, the demand for connectors has surged, leading to an increasingly heavy load of contour dimension inspection tasks.

Traditional inspection methods typically depend on operators using calipers, projectors, and image measuring instruments. These methods require highly skilled personnel and are fraught with drawbacks such as inaccuracy, low efficiency, and excessive labor costs, all of which severely hamper production efficiency.

In the mass production of connectors, there is a pressing need for a measurement instrument that is swift, efficient, and immune to human error.

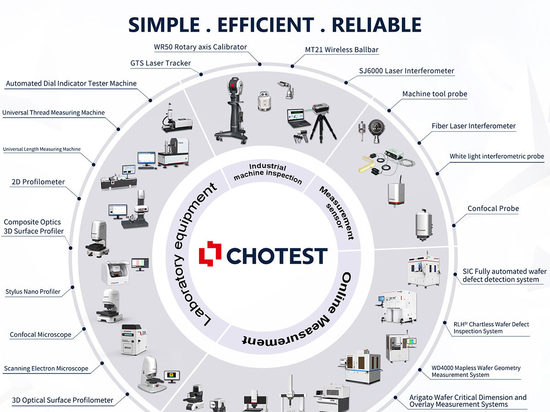

CHOTEST Inspection Solution

CHOTEST’s VX series flash testers seamlessly integrate telecentric imaging with intelligent image processing software, transforming any complex measurement task into a simple one. Just place the connector on the stage, press a button, and all dimensions are measured in an instant.

1. High Efficiency

The flash tester achieves high efficiency in measurement. With just one click, measurements can be completed within seconds, capable of measuring up to 512 positions at a time. In CNC mode, batch measurements can be conducted. Additionally, the flash tester's automatic recognition feature allows for measurements without the need to position the product precisely.

2. Good Accuracy

The flash tester's automatic focusing and part recognition reduce the operator's influence on the measurement results. The same product can be measured repeatedly with high consistency, and different operators can achieve the same measurement results.

3. Simple Operation

Simple operation is one of the main features of the flash tester. It can be operated with just a mouse, and even novices require only minimal training, making it relatively undemanding for operators.

4. Convenient Data Processing

The flash tester can automatically generate inspection reports with one click and automatically output SPC analysis reports, making it convenient and quick.