#Product Trends

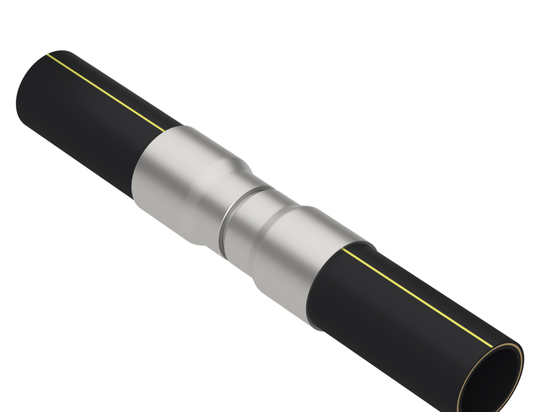

FRP pipe

FRP stands for Fiber Reinforced Plastic

FRP pipes are a type of non-metallic pipe made by reinforcing plastic materials with fibers, often glass fibers. These pipes are also known as GRP (Glass Reinforced Plastic) pipes. They are commonly used in various industries due to their corrosion resistance, lightweight, and durability. Here are some key points about FRP pipes:

Materials: FRP pipes are typically made from a combination of thermosetting resin (such as polyester or epoxy) and glass fibers. The fibers provide strength and reinforcement to the plastic matrix.

Corrosion Resistance: One of the primary advantages of FRP pipes is their excellent resistance to corrosion. They can withstand exposure to corrosive chemicals and environments, making them suitable for industries like chemical processing and wastewater treatment.

Lightweight: FRP pipes are lightweight compared to traditional metallic pipes, which can make installation easier and reduce transportation costs.

Smooth Interior: FRP pipes have a smooth inner surface that promotes good flow characteristics, reducing friction and energy loss.

Customization: These pipes can be manufactured in various diameters and lengths to meet specific project requirements.

Insulation Properties: FRP has good insulating properties, making FRP pipes suitable for applications where electrical insulation is important.

Longevity: When properly designed, installed, and maintained, FRP pipes can have a long service life.

Applications: FRP pipes are used in a wide range of industries, including chemical processing, water and wastewater management, oil and gas, power generation, and marine applications.