#Product Trends

Conprofe Ultrasonic-Green Solution Enables Less Burrs and Lower Cost in Cervical Cage Machining

Conprofe Ultrasonic-Green Solution Enables Less Burrs and Lower Cost in Cervical Cage Machining

A cervical cage is an inter-body implant for the treatment of cervical joint diseases. As the workpiece needs to be implanted into the human body, the machining accuracy, surface quality and cleanliness of the cervical cage machined need to be strictly controlled. Otherwise, it may cause defective workpieces, or oven endanger human life.

Today, we would like to introduce an innovative solution for cervical cage machining - Conprofe Ultrasonic-Green Machining Solution. After comparison, we found the Conprofe solution can significantly improve surface quality, extend tool life, and reduce machining cost.

Challenges

The cervical cage, made from PEEK (polyetheretherketone), has a higher coefficient of thermal expansion than metal and is prone to burr and deformation during machining. Originally, the customer's used an internationally renowned 5-axis machine tools and coolant, which resulted in serious burrs, making difficult, inefficient and costly de-burring necessary. In addition, the coolant left on the workpiece need to be cleaned, increasing machining cost.

Conprofe Solution

Conprofe solution combines Conprofe Ultrasonic-Green Engraving and Milling Center UGM-500 with a Smartguy 5-Axis Rotary Table and a Supercritical Carbon Dioxide (ScCO2) Cryogenic Cooling System. The Smartguy 5-Axis Rotary Table is adopted to realize 5-axis positioning and 5-axis simultaneous machining, meeting the requirement of geometrically complicated surface machining and drilling of PEEK cervical cage. And the Supercritical Carbon Dioxide (ScCO2) Cryogenic Cooling System plays a key role in cooling and lubricating the tool, and thus extending tool life by converting the supercritical CO2 fluid into a low-temperature cooling medium of -78°C.

1、Ultrasonic-Green Engraving and Milling Center UGM-500

Features:

All-in-one machining center for hard-brittle materials, metal parts, composite materials, high gloss/mirror finish, etc.

HSK-E32/HSK-E40 ultrasonic spindle with a max. speed of 40,000 rpm available

Supercritical Carbon Dioxide (ScCO2) Cryogenic Cooling System or MQL system available for clean machining

Extended Tool Magazine available to meet various machining needs

Rotary tables addable to realize 5-axis simultaneous machining of geometrically complex parts

SIEMENS 808D/828D systems available

2、Supercritical Carbon Dioxide (ScCO2) Cryogenic Cooling System

Features:

50%~100% higher machining efficiency in machining hard-to-cut materials

Longer tool life with reduced friction between the cutter and the workpiece

Higher machining accuracy thanks to reduced machining residual stress

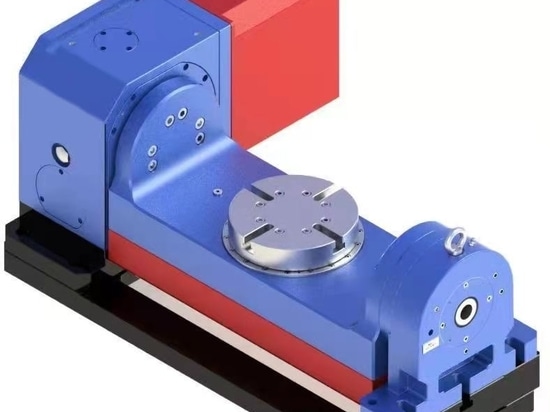

3、Smartguy Tilting 5-axis Rotary Table

Features:

High precision with large travel

Built-in hydraulic brake structure for heavy-duty cutting

Compatible with a variety of motors

Compact and easy to set up

Machining Effects

Compared with traditional machining, Conprofe Ultrasonic-Green solution reduces the burrs by 80% and improves the tool life by more than 30% in PEEK cervical cage machining, realizing clean machining with no need for coolant. The advantages of the Conprofe Ultrasonic-Green solution are obvious.