#Trade Shows & Events

Conprofe Showcased Ultrasonic-Efficient Machining Solution for NEV Brake Discs at the Yantai Brake Disc Seminar!

Conprofe Showcased Ultrasonic-Efficient Machining Solution for NEV Brake Discs at the Yantai Brake Disc Seminar!

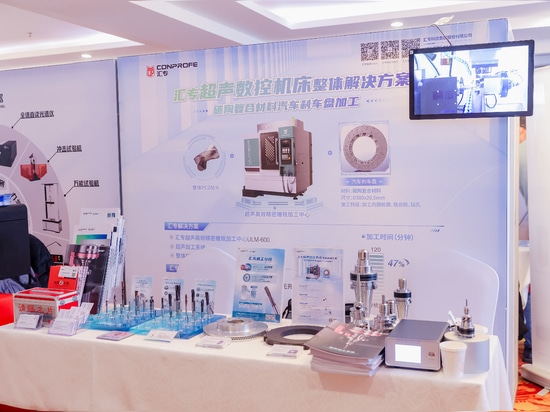

On December 19, the Seminar on New Material, New Technology, New Craft and New Equipment for Brake Disc was grandly held in Yantai, Shandong Province, China. As a provider of Efficient, Green, Intelligent Manufacturing Solutions and Key Units, Conprofe showcased its Ultrasonic-Efficient Machining Solution for NEV Brake Discs.

Conprofe Ultrasonic-Efficient Machining Solution for NEV Brake Discs featuring Conprofe Ultrasonic CNC Machine Tools plays a key role in its machining solutions. Additionally, based on different machining materials and requirements, machine tools can be equipped with Solid PCD cutting tools.

Conprofe's Ultrasonic CNC Machine Tools and Solid PCD Cutting Tools together or on their own have demonstrated excellent performance in reducing workpiece chipping, improving workpiece surface quality, tool life and machining efficiency in brake disc machining.

In a case of Carbon-Ceramic Composite brake disc machining, Conprofe's solution reduced the cycle time by 47%, while bringing significant surface quality improvement.

At the booth, Conprofe also showcased its featured products: Ultrasonic Machining System, Ultrasonic Tool Holders, Solid PCD Thread Mills, and Precision Tool Holders, as well as the typical workpieces of the industry.

Brake disc is a crucial component of the auto braking system. With increasing NEV output, the industry's demand for new materials, new technologies, new processing technologies, and new equipment for brake disc manufacturing continues to rise in the coming years. Conprofe strives to explore more innovative machining solutions for our customers in the promising market.

Conprofe Case Exhibition

(1) Carbon-Ceramic Composites--- NEV Brake Disc Machining

Material: Carbon-Ceramic Composites

Dimension: D380x20.5mm

Machining Feature:Internal grinding, step milling, hole drilling

Traditional Solution:

× Severe tool wear from grinding high-hardness material

× Chipping, delamination, fiber pull-out and hole edge cracking issues

× Low machining efficiency (C/T 120min)

Conprofe Solution:

+ Conprofe Ultrasonic Precision Engraving & Milling Center ULM-600

+ Ultrasonic Machining System

+ Solid PCD Drill

Conprofe Machining Advantage:

√ Improved surface quality with no obvious clipping, cracking, delamination or fiber pull-out

√ Cycle time down by 47% from 120 min to 64 min

(2) AlSiC Brake Disc Hole Drilling

Material: AISiC

Dimension: D258x46mm

Machining Feature: D4x45.5mm Holes(Depth-Diameter Ratio11:1)

Traditional Solution:

× Hard-brittle material, easy to break

× Poor tool life: < 5 holes/tool, unavailable mass production

× Quality failure from severe hole exit edge flanging

× Long cycle time: 530s/hole

Conprofe Solution:

+ Conprofe Ultrasonic-Green Vertical Machining Center MVA-856

+ Ultrasonic Machining System

+ Solid PCD Drill

Conprofe Machining Advantage:

√ No burrs or flanging at hole edges

√ Tool life improved by 9 times to 50 holes/tool

√ Cycle time shortened by 51%, from 530s to 260s per hole

If you are interested in learning how Conprofe's Ultrasonic Machining Solution will benefit your workshop, please don't hesitate to contact us!

TEL: +86-20 138 2607 9999 (Esther.Hu--- Senior Director )

Email: esther.hu@conprofetech.com