#Product Trends

AENOASA launched Handheld Ultrasonic Pneumatic Drill, drilling composite materials with high quality and efficiency

AENOASA Handheld Ultrasonic Pneumatic Drill

Applications and Challenges of CFRP

Carbon Fiber Reinforced Polymer (CFRP) possesses prominent advantages such as light weight, high specific strength, large specific modulus, and excellent anti-vibration effect. The structure of aircraft, mainly made of CFRP, could achieve a 20%-30% reduction of the overall weight.

Despite the numerous advantages of CFRP, being a hard-to-cut material, its application and promotion still have significant limitations. In the drilling of CFRP components of aircraft, problems including high cutting resistance, delamination, fiber pull-out, and severe breakage have always happened.

AENOASA Handheld Ultrasonic Pneumatic Drill

Therefore, AENOASA upgrades traditional pneumatic drill with ultrasonic technology, thus developing Handheld Ultrasonic Pneumatic Drill. With ultrasonic vibration on the drill bit, cutting force is significantly reduced, leading to improved efficiency and hole quality.

AENOASA has introduced four models of handheld ultrasonic pneumatic drills: Basic, Enhanced, Smart, and Variable Speed Smart, catering to different customers’ needs.

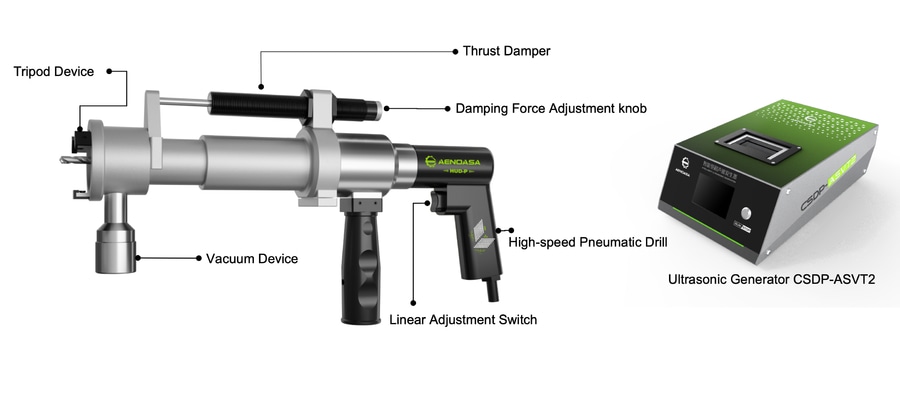

1. Basic Handheld Ultrasonic Pneumatic Drill HUD-P

HUD-P is the lightest, weighing only 1.9kg, making it easy and flexible to operate.

2. Enhanced Handheld Ultrasonic Pneumatic Drill HUD-PM

Enhanced Version, compared to Basic one, has improved in speed, ultrasonic amplitude and power.

3. Smart Handheld Ultrasonic Pneumatic Drill HUD-P60-SVT/HUD-P185-SVT

The Smart Version is an upgrading product, incorporating Ultrasonic Amplitude Adaptive Function and Thrust Damper, improving the drilling perpendicularity of and hole exit quality.

HUD-AP60-SVT/HUD-A185-SVT

4.Variable Speed Smart Handheld Ultrasonic Pneumatic Drill

HUD-AP60-SVT/HUD-A185-SVT

The Variable Speed Smart version, on the basis of the Smart version, adds a linear adjustment switch for speed control.

Seven Highlights

1. Applicable to wide range of materials with ultrasonic amplitude of 12~18μm and Max. Speed of 4000~18500r/min

2. Effectively inhibiting delamination, reducing tearing and producing better drilling quality

3. Effectively reducing cutting force and labor intensity, and improving machining efficiency

4. Significantly reducing tool wear and extending tool life

5. Improving drilling perpendicularity and hole exit quality with Thrust Damper

6. Ergonomic design for more stable hand control

7. Flexible operation, suitable for mobile drilling operations in limited space

Unique Advantages of Ultrasonic Technology

AENOASA Handheld Ultrasonic Pneumatic Drill is equipped with ultrasonic drilling technology with independent IPR. This technology converts high-frequency electrical energy into mechanical vibration, which makes the rotating drill bit vibrate thousands of times per second and separate the drill and the workpiece periodically.

01 Cutting Force Reduction

This method not only reduces the average cutting force but also facilitates heat dissipation, thereby lowering the cutting temperature. The maximum cutting force for traditional machining is 50N, while for ultrasonic machining, it is a maximum of 27N. The cutting force in ultrasonic machining is reduced by 46% compared to traditional machining.

02 Smoother Chip Removal

At the same time, compared to traditional drilling, ultrasonic vibration drilling enables better chip breakage and chip removal.

Application——Carbon Fiber Reinforced Plastic (CFRP) Plate Drilling

For example, in a case where a customer uses AENOASA Handheld Ultrasonic Pneumatic Drill with Intelligent CNC Ultrasonic Generator for perforating CFRP plates, it effectively reduces tool wear and enhances hole quality.

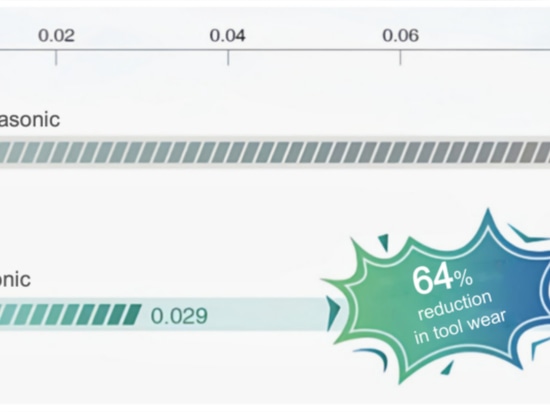

1 Tool wear comparison between traditional and ultrasonic pneumatic drilling

The maximum tool wear is 0.08mm with traditional pneumatic drill; With ultrasonic

pneumatic drill, the tool wear is only 0.029mm, a reduction of 64%.

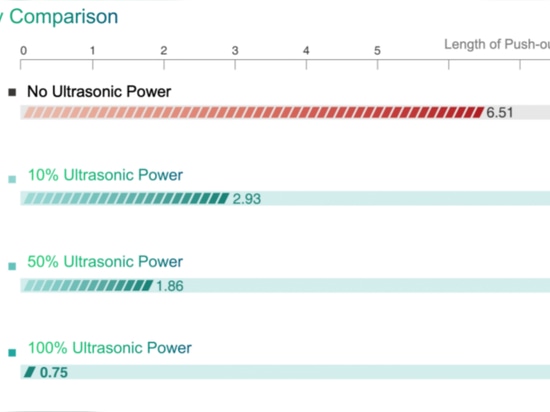

2 Comparison of tearing length under different ultrasonic power outputs

The test shows that the performance with ultrasonic is significantly better than that with traditional drilling (non-ultrasonic). There is serious delamination after traditional drilling with the tearing length of 6.51mm. With ultrasonic power increases, the hole’s tearing length decreased to 0.75mm, a remarkable reduction of 88%!

If you have machining needs in the aerospace field, feel free to contact us!