#Industry News

Case Sharing: 55xD Micro Hole Drilling in Single Crystal Silicon Showerhead with Ultrasonic CNC

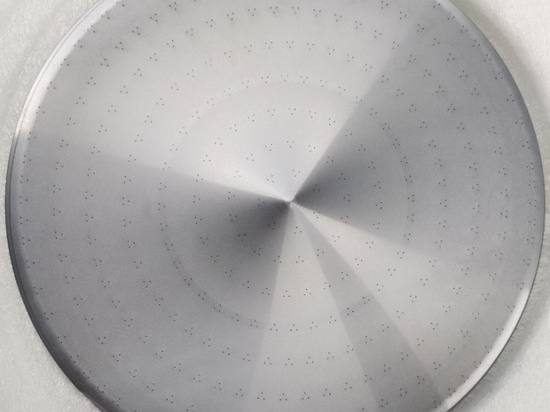

Case Sharing: 55xD Micro Hole Drilling in Single Crystal Silicon Showerhead with Ultrasonic CNC

Silicon, Single-Crystal Silicon and Silicon Carbide are the most popular materials for semiconductor showerheads, which require many micro-deep holes. Laser is one common way to make the holes. However, the disadvantages of laser are also obvious, such as poor surface quality, long cycle time and inconsistency of holes.

More and more manufacturers have begun to turn to CNC solutions. Yet the hard-brittle properties of these materials easily result in hole edge chipping, poor hole wall surface quality and precision, low yield, poor tool life and low efficiency, not to mention the high cost of each workpiece. Take our customer as an example. They aim to drill many D0.45mm 55xD micro-deep holes in one Single Crystal Silicon Showerhead.

Workpiece: Semiconductor Showerhead

Material: Single Crystal Silicon

Hole Dimensions: D0.45mm*24.75mm

At first, they tried two-sided drilling because the holes were too deep, easily causing tool breakage. The cutter marks inside the holes where the two-sided drilling met were also a big challenge. Moreover, the drill's poor rigidity and vibration worsened the hole wall surface quality and pendicularity.

Challenges:

- Hole wall roughness Sa ≥6.54μm

- Hole roundness ≥0.025mm

- Unable to control hole perpendicularity

To tackle the customer's problems, Conprofe provides a hybrid solution with its Ultrasonic Machine Tool and Solid PCD Micro-Drill. With Ultrasonic Drilling, 16kHz to 60kHz of micro-vibrations are applied to the drill bit. The drill bit periodically contacts and separates from the workpiece, reducing cutting force by 40%.

The results of Ultrasonic Drilling are stunning:

1. Continuously drill over 2,000 ultra-deep micro-holes with one Solid PCD Drill

2. No observable chippings around hole edges

3. Hole roundness up to 0.003mm

4. Hole wall roughness down by 99.8%, from Sa 6.540μm to Sa 0.013μm

If you are also working with Hard-Brittle Materials in Semiconductors or other industries, especially if you are in search of Ultra-Deep Micro-Hole Drilling Solution, you are welcome to contact us and learn more about Ultrasonic Machining benefits!

Ms. Esther HU

Senior Sales Director

Tel/WhatsApp: +86-138 2607 9999

Email: esther.hu@conprofetech.com

Web: www.conprofecnc.com