#Product Trends

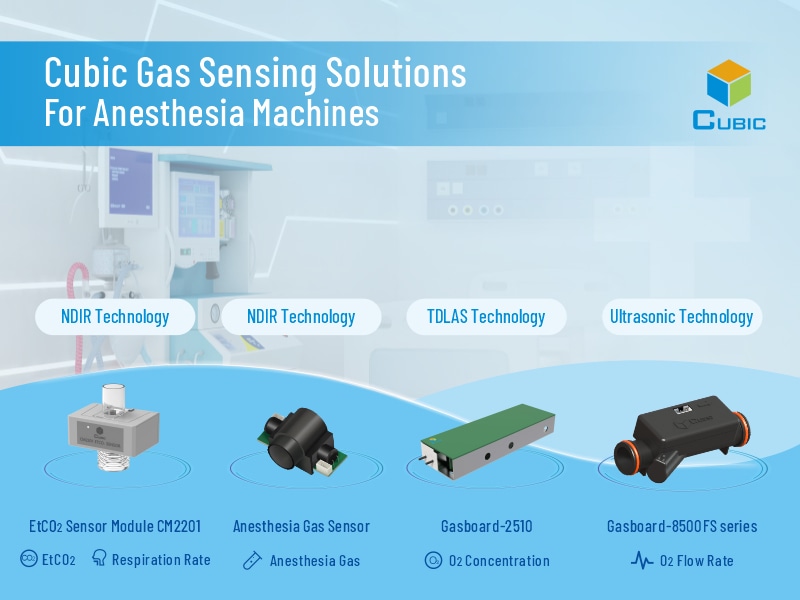

Cubic Gas Sensing Solutions for Anesthesia Machines

How Cubic Advanced Gas Sensors Assist in Anesthesia Machines?

The purpose of an anesthesia machine is to deliver precise amounts of anesthetic gases or medications to patients during surgical procedures to maintain anesthesia. Throughout this process, closely monitoring key respiratory parameters, including EtCO2 (end-tidal carbon dioxide concentration) and oxygen levels, could ensure the patient's respiratory function remains normal and safe.

Given that metabolic carbon dioxide (CO2) is transported from the blood to the lungs and then exhaled during breathing, EtCO2 levels can serve as indicators of the body's physiological condition. Monitoring EtCO2 during the use of anesthesia machines can assist medical professionals assess a patient's ventilation status and provide early warning of respiratory compromise. Based on the dual beam non-dispersive infrared (NDIR) technology, Cubic mainstream EtCO2 sensor module CM2201 has been specially developed to monitor the respiratory end tidal CO2 concentration and respiration rate. Leveraging the NDIR principle, Cubic CM2201 exhibits high selectivity, enabling accurate measurement of CO2 concentrations without interference from other gases. With the feature of fast response time, CM2201 ensures timely and precise monitoring. Additionally, constructed from durable materials with excellent stability and no wearing parts, CM2201 boasts a long service life and low maintenance costs. Beyond its core performance, the modular design of CM2201 ensures compatibility and easy integration into monitors and anesthesia machines with an 8-pin socket.

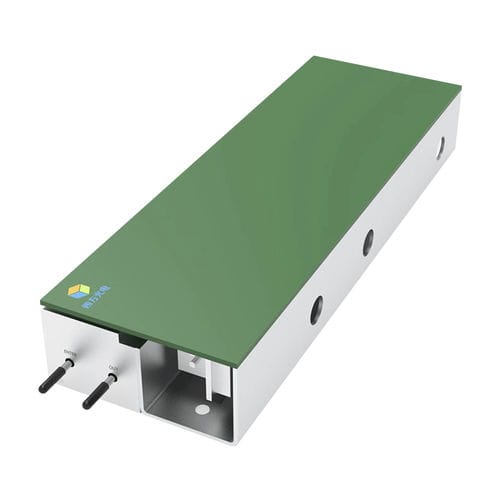

In addition to monitoring EtCO2, closely tracking oxygen concentration could ensure that patient's breathing oxygen levels remain within a safe range during the surgical procedure, avoiding situations of oxygen toxicity or hypoxia. Cubic has specifically designed Gasboard-2510 oxygen sensor for accurate oxygen concentration measurement. Based on the principle of TDLAS (Tunable Diode Laser Absorption Spectroscopy), Gasboard-2510 oxygen sensor could realize high accuracy and excellent repeatability, with a measurement range of 0%~100% level and a resolution up to 0.01. Utilizing narrowband tunable laser emission targeting oxygen absorption band, Gasboard-2510 achieves high selectivity of oxygen gas. Furthermore, it boasts fast response time of less than 170 milliseconds. Therefore, Gasboard-2510 oxygen sensor can be widely applied in anesthesia machines that demand accurate, reliable, and rapid oxygen concentration measurements.

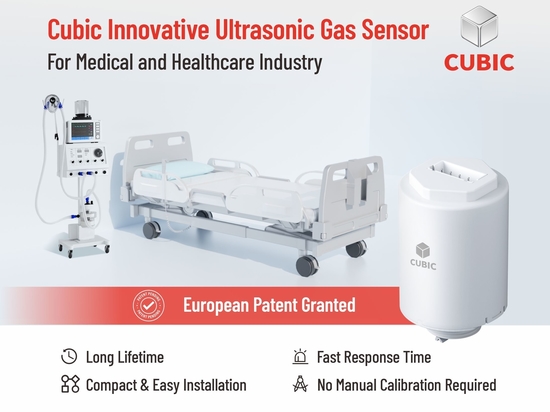

Simultaneously, to ensure patients receive adequate and consistent oxygen supply during surgery, medical professionals must have access to oxygen flow rate measurements to promptly identify and rectify any oxygen supply issues, ensuring patient safety. Cubic has designed oxygen flow rate sensors to accommodate varying flow rates: Gasboard-8500FS series, developed to handle flow rates of up to 300 L/minute. By adopting ultrasonic detecting technology and principle of TOF (time of flight) measurement, Cubic oxygen flow rate sensors have remarkable characteristics of excellent stability, high accuracy, fast response, continuous monitoring, etc.