#Product Trends

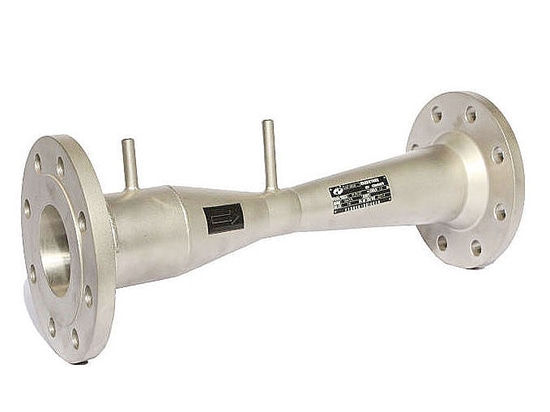

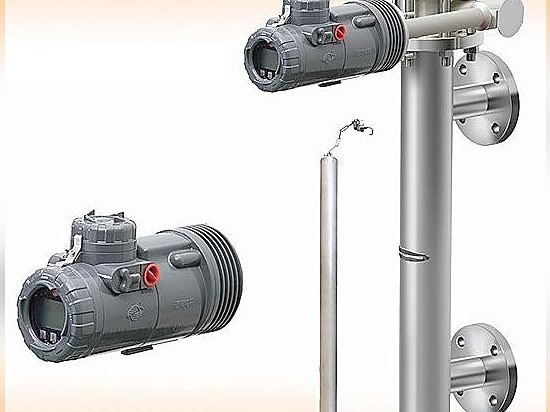

Displacer level transmitter--DDTOP&FISHER

The liquid level changing triggers the change of the buoyancy of displacer, then it will be transferred into the torque tube unit. This makes the torque tube and core axle rotate synchronously.

At the same time, the magnetic steel parts that fixed at the core axle of the torque tube turn rotary displacement. The Hall-effect sensor senses the magnetic field change and converts the magnetic signals into current signals. DLC3010 series smart level controller measures process variables with a controller and relative electronic circuit, supplies current output to drive LCD and support HART communication. Controller receives the electric signals that have been temperature-compensated and linearised. Meanwhile, compensates the liquid density change caused by the change of the process temperature, then supplies 4~20mA current output signals. LCD can indicate analog output, process variables, process temperature (if RTD is installed), degrees of the torque tube rotation and percent range of variable, etc.

Power supply: 12~30V DC;

Output signal: 4~20 mA DC

Measuring range: 300mm—6000mm

Nominal pressure: ≤42.0Mpa

Nominal diameter: DN40 or as customers'' request

Ambient temperature: –40ºC to +80ºC (when ≤–30ºC, no LCD display)

Operating temperature: –70ºC to +400ºC

Measuring accuracy: 0.5%

Influence from power supply: When the voltage of the power supply varies between min. and max. ,the output change is within <±0.2%. of the full scale.

LCD display: Output current signal、process variable、process temperature、percentage range、rotation angle of torque tube.

Medium density difference: ≥0.08g/cm³

Material of torque tube: Standard configuration Inconel 600,or Monel, HasetlloyC-276

Wetted material: 304、316L or as customers'' request

Flange standard: HG/T20592-2009、HG/T20615-2009 or as customers'' request

Power entry: Two NPT 1/2 (female thread) or as customers'' request

Explosion-proof: Explosion isolation ExdⅡCT6, Intrinsically safe ExiaⅡCT6

Protection grade: IP66

Alarm jumper: For the self-diagnosis to the inaccuracy failure of the process variables (for example, the electronic module failure). Configure the process variables of high and low alarms.