#Product Trends

Industrial vacuums for semiconductor materials

Clean and safe working environment, highest quality of final product

Industrial vacuum cleaners are an essential component in the production of electronic components (chips and printed circuit boards), a process that requires extremely clean environments and high standards of precision. The presence of even the smallest dust particles or metal debris can impair the functionality of microchips, causing defects or reducing production yield. In particular, vacuum cleaners are very useful for sucking up semiconductor materials used in manufacturing.

Why are industrial vacuum cleaners essential in electronic component production?

The production of electronic components (chips and circuit boards), which are essential for making devices such as computers and smartphones, requires meticulous cleaning because of their extreme delicacy and precision required. An industrial vacuum cleaner is necessary to vacuum the semiconductor materials involved in these processes, such as:

- Silicon (Si)

- Gallium Arsenide (GaAs)

- Silicon Carbide (SiC)

- Gallium Nitride (GaN)

In particular, vacuum cleaners can ensure a clean environment that meets industry standards and are useful in the:

- Prevention of manufacturing defects: remove residues that could cause defects, reducing scrap and operating costs.

- Protection against chemical and physical contaminants: captures contaminants that could alter the electrical properties of semiconductors, preserving their quality.

- Dust collection of precious materials.

- Safeguarding operators and the environment: ensure operator safety and proper waste management to reduce environmental impact.

HEPA filtration for safe vacuuming

In the production of electronic components, the use of vacuums equipped with HEPA filters is essential to ensure a contamination-free production process. During processing stages, extremely fine particles are generated, posing a serious threat not only to the quality of the final product but also to the health of exposed operators.

These powders include metal residues, silicon dust, and other particles resulting from mechanical and chemical processes. Our vacuums equipped with HEPA filters are designed to capture even the smallest particles, offering a filtration efficiency of over 99.995% for particles as small as 0.18 microns.

ACD and ATEX vacuum cleaners for handling potentially combustible dust

Certain steps in the manufacturing process of chips and PCB generate fine dust that can become explosive under certain conditions if not handled properly.

- Conductive Metals (Aluminum, Copper, Silver).

- Crystalline Silicon and Silicon Carbide.

- Resin Powders and Plastic Materials.

- Powders from Chemical Processes.

- Carbon-Based Compounds and Organic Materials.

To ensure maximum operational safety, it is essential to analyze the materials used and their inherent characteristics in order to choose the best vacuum solution available: standard industrial vacuum cleaners, ACD-rated or ATEX-certified.

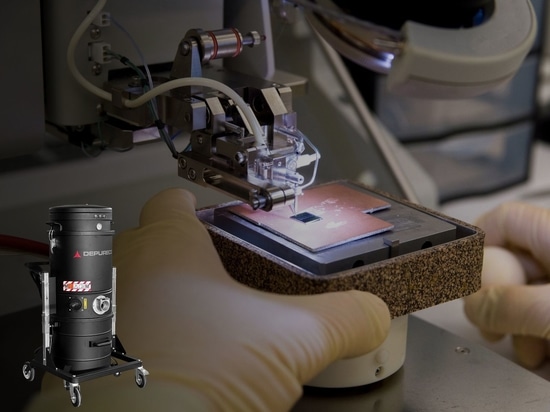

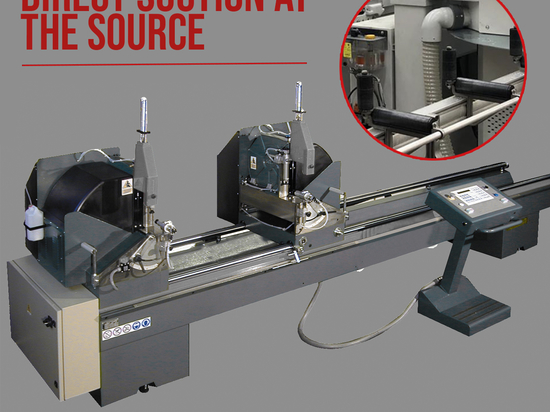

Effective waste management at the workbench

In these manufacturing processes, the workbench is one of the most critical environments in terms of the accumulation of dust and waste generated by the cutting, etching, and assembly processes of electronic components. The safe management of scrap on the workbench requires the use of efficient and versatile vacuum systems that can quickly remove fine dust and processing residues. A proper vacuum system keeps the work area clean and compliant with safety standards, ensuring operational continuity and reducing downtime due to the need for manual cleaning.

For these applications, the XM 20 vacuum cleaner with an H14 filter for very fine dust is the ideal solution. Compact and handy, it offers power and reliability for waste collection even in small spaces.

Precious metal recovery

The use of precious metals such as gold and copper is essential to ensure the quality and efficiency of components in electronic chips. These materials are employed, for example, in wire bonding and other critical production stages. However, during the manufacturing processes, some of these metals can disperse in the form of dust or particles, creating potential economic losses and environmental risks. We offer customized vacuum solutions designed to effectively recover precious metals, minimizing waste and improving the sustainability of the production process.