#Industry News

THE DEVELOPMENT OF THE AUTOMATIC BAR STEEL STRAPPING MACHINE

Packing of Rebars--From Manual Binding to Automatic Bundling and Strapping

The quality and appearance of the metal products are becoming more and more important under the status of the modern market economy, accordingly, the requirement for the modernization of steel company has been increased year by year.

More and more Steel company that produce steel rods and bars realized that the good quality of packing is the key to guarantee the large output for steel bar produce, which the traditional way of packing and the harsh environment for workers can never make, it’s becoming even worse when the steel bars trip off or mix up after bundling and strapping, furthermore ,one cycle for manual strapping will be done through 12 complicated procedures, which are strap inserting, opening gripper, release handle, strap feeding, putting seal, tensioning, strap cutting, release handle, crimping, releasing gripper, pushing down, etc.

http://chinasuperworker.com/wp-content/uploads/2017/10/steel-rod-packed-by-manual-banding-tool.png

pneumatic banding tool, pneumatic strapping tool

As a result, strapping by manual banding tool severely restraints the number of bar steel productivity. To solve this problem, all the Steel company employ the Automatic Industrial Packing System, from which the steel bar factories benefit greatly, such as, each strapping positions accurate, it accelerates the strapping speed, reduces the labor cost and strapping waste, frees the workers from extreme working conditions, and save seal cost for each strapping etc.

More than a decade ago, The domestic famous steel companies such as Shougang Group、Tanggang、Baogang Steel had to import the Automatic Industrial Strap Packing System from foreign company due to the lack of reliable strapping technology from the domestic company, but the problems are, importing this automation system not only cost the huge amount of foreign currency, the cost for the strapping machines is extremely high, the difficulty of maintenance had been a headache to them.

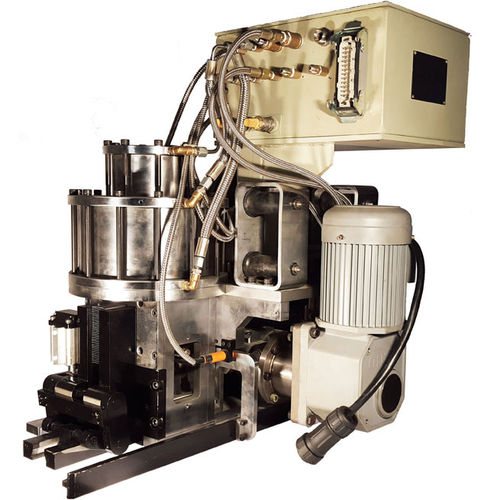

During our repair and maintenance service provided for the imported top brand automatic strapping machines used in Shougang group, Shenzhen Superworker Technology Company committed to developing innovative technology for Automatic strapping machine of our own since 2008,after years of researching and studying a wide variety of strapping machines from both at home and abroad, combined with profound understanding of steel production, its self-developed automatic bar steel strapping machine came into the market in 2011.

Since the first Superworker automatic strapping machine started to be trial used in Shougang Group, it attracted other large Steel Companies to use it in their steel bar production mills and they are recognized as the most reliable automatic strapping machine they’ve ever used, so far the most wildly used in Bar steel banding machines are our two types of patented ones, which are the flanged notching sealless joint type automatic steel strapping machine and automatic ultrasonic welding PET strapping machine.

The automatic strapping machines other major brands produce are applying the sealless notching joint and the welding joint for steel banding machines, a small percent of seal type automatic strapping machines are still being produced and used in steel plants. However, these 3 connections cannot prevent the strapping closure tripping off during transportation. Therefore, Superworker technology develops the strapping head which can add 2 flanges to the steel band overlap and lowers the rate of loose connection to ZERO (0%).

http://chinasuperworker.com/wp-content/uploads/2017/10/steel-bar-rod-strapping-by-automatic-strapping-machine.jpg

steel bar strapping, rebar banding, steel rod strap packing

bar steel packed by automatic steel strapping machine

The strapped bar steel can always be kept in right place during the process of transportation. Considering the Joint efficiency is up to 90% of the strapping itself, and the cycle time for one belt strapping is only 28s, there’s no doubt that it really increases the working efficiency of the bar steel plant or reinforced bar factories, besides, Superworker automatic strapping machines are characterized by its modular design and high reliability, which can easily be adapted to all working conditions in bar steel plants such as high temperature working environment、shocking environment, dusty environment etc.