#Industry News

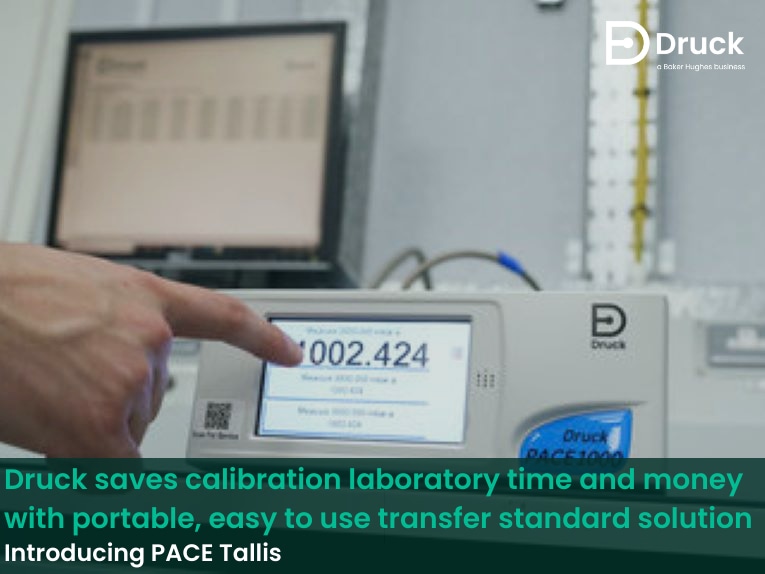

Druck saves calibration laboratory time and money with portable, easy to use transfer standard solution

Druck solutions

The customer

Our Applications Engineer was approached by an accredited calibration laboratory, with the aim to find a new modern, cost-effective device to support their primary lab standard.

Throughout this consultative process, we were able to present the latest innovation to the PACE product line, the PACE Tallis transfer standard calibrator. This application note outlines how PACE Tallis has met, and often exceeded, the customers’ requirements for an easy-to-use, high performance transfer lab standard.

The function of a calibration laboratory is to perform the calibration of various different sensing equipment from a range of applications and industries with varying different accuracies and uncertainties. A traceable reference standard is required to calibrate the device under test (DUT) against, this is commonly known as the transfer standard. This transfer standard is traceable back to a primary standard either belonging to the calibration lab itself or to an external metrology institute.

Customer challenge

This customer uses deadweight testers (DWT) as its primary and transfer standards.

These devices have been used for decades in labs across the globe and are high in price, large in size and difficult to set up and service. To use a DWT efficiently, a technician must undergo, often extensive, training courses. The customer has recently had high staff turnover, meaning experienced technicians are stretched, and must train new staff how to operate DWTs.

The customer has also expressed concerns about the servicing and maintenance cost of a DWT. With a traditionally high price point, the DWT also required regular maintenance and servicing, including the cleaning of pistons etc. This additional expense has forced our customer to consider alternate options for their transfer standard.

The Druck solution

To solve this issues presented, our Applications Engineer demonstrated Druck’s PACE Tallis, a new transfer standard, designed for test bench, bench top and panel mount applications.

With minimal instructions given, the customer was able to calibrate the transfer standard against their own primary standard and perform a calibration of various other devices using the PACE Tallis. The Calibration was completed using the touch screen display after an easy set up and installation process.

Inline with the published uncertainties of the product. Which was better than the DWT it was replacing.

PACE Tallis is also a much smaller lab standard compared to the cumbersome DWT alternative, meaning the customer is able to maximise space in their facility for customer units and/or equipment.

Positioned at a lower product cost of a typical DWT, PACE Tallis requires minimal servicing and has a lower risk of damage during use and transportation. With no need to clean pistons, the customer was impressed with the significant lifetime cost savings that PACE Tallis offered. The potential for reduced downtime with calibration and servicing was also a benefit to our customer. With a scope for more customer calibrations, Druck’s customer is seeing the added benefits of utilising PACE Tallis.

Where Druck adds value

PACE Tallis utilises the latest advancement TERPS (Trench Etched Resonant Pressure Sensor) technology which is a silicon based pressure sensing technology, unique to Druck. The characteristics of TERPS tecnology delivers market leading accuracy, stability and precision with the all benefits of a digital system. The integration of TERPS with PACE Tallis results in comparable performance to traditional DWTs.

Reducing human error in the calibration process is a factor that Druck’s customer benefitted from. Combining PACE Tallis with Druck’s 4Sight2 calibration management software completely automated the calibration process, not only eliminating human error, but creating traceable, audit ready data and realising time savings.

Compared to a traditional DWT, PACE Tallis is a much smaller, portable device that does not compromise on performance. The design of PACE Tallis opens new applications for calibration in remote and sub-optimal locations.

Utilising over 50 years of experience and pedigree in pressure measurement and sensing, Druck is uniquely positioned to support customers across the globe with their pressure challenges.

Talk to the experts in pressure to find a solution for your application.

Find out more at Druck.com/PACE-Tallis

Performance benefits

Lower risk of errors during use (automated software vs user error).

No effects of physical quantities to impact error budget (e.g. local gravity / density of the media).

Easy setup and operation.

Calibrated across a wide temperature range.

Guaranteed uncertainty budget (e.g. no induced errors due to poor piston cleanliness.)

Low cost of ownership

Lower product cost than a typical DWT

Minimal servicing required (no cleaning of pistons etc.)

Automated software vs experienced and well trained manual operators

Reduced shipping costs for calibration.

Less “real estate” required for physical product.

No need for expensive vacuum pumps, custom test benches

Miscellaneous

Portable - for calibrations in remote and sub-optimal conditions.

Lower risk of damage during use/transportation (robust sensor vs pistons, mass sets etc.)