#Product Trends

DST develops innovative agitator drives

DST recently supplied a new type of agitator for a customer in the pharmaceutical industry. The special requirement here was the ability to stir both on top and underneath.

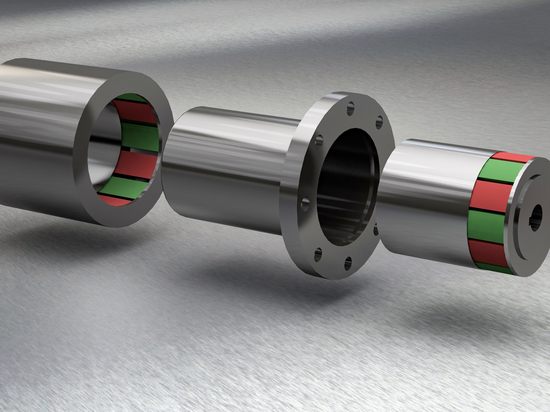

Agitators are used as the heart of reactors or process engineering machines and ensure a powerful, safe and efficient mixing process. No foreign particles or substances can get into the medium to be mixed from the outside, nor are any gases or liquids able to escape into the environment. The agitators are available as top-mounted and bottom-mounted versions, depending on the area in which the drive is used. DST has now succeeded in designing a compact magnetic drive that can be used universally for both applications due to a uniform design of the components. The special feature here is the bearing configuration of a special SSiC bearing arrangement consisting of axial and radial bearings, which enables flexible installation. This is further enhanced by the standardization of the connections, which also allows customers to standardize their own components.

The new drive was designed for a torque of 0.5 Nm, which in the future will also be scalable up to 600 Nm. In principle, the new development can be realized in any material approved in the pharmaceutical industry and, due to the gas-tight welding of the inner and outer rotor, meets the high safety standards in this industry. To achieve a surface finish finer than Ra 0.6 µm, the drive was additionally electropolished. Although the new development consists of 30 individual components, it weighs only 700 grams, making it a compact solution for mechanical engineering.

Another advantage of the new drive is simplified cleaning. Since the drive unit is located outside the tank and is therefore not in contact with the media, it is also not necessary to disassemble it before cleaning. Standard cleaning procedures such as CIP (clean in place) or SIP (steam in place) can therefore be used. This results in considerable time savings for the customer.

Optionally, DST can provide an extension for customer-side system monitoring such as speed or temperature monitoring. In addition, materials with FDA approval can be used for the new development, which also enables use in the food industry.