#Product Trends

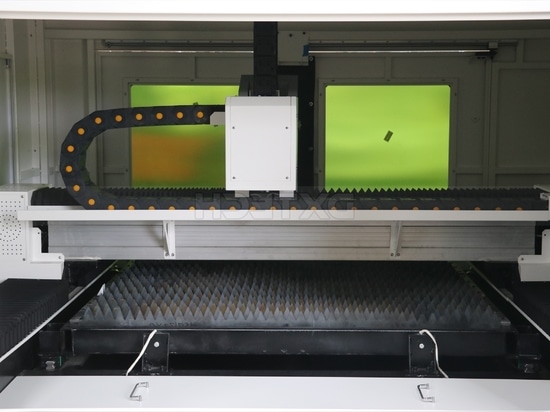

High-precision Small Fiber Laser Cutting Machine

HIGH-PRECISION SMALL FIBER LASER CUTTING MACHINE ADVANTAGES

This small fiber laser cutter is the best choice for users with limited budget and small-scale metal processing projects, such as metal tools making, small metal parts making, metal ornament designing and so on.

1. Strong stability, high precision, and with no deformation for 20 yearsThe carbon steel structure has good toughness, excellent ductility, and great welding and heat treatment performance. Besides, the stress annealing and vibration aging function are used to deal with the stress in the welding and machining process of the machine tool, so that the machine is more durable.

2. High precision linear motorAdopts a high-precision linear motor, which has the features of compact structure and low power consumption. In addition, there is no mechanical contact and less friction. Moreover, it has the advantages of smooth motion, high positioning and repositioning accuracy, high speed and acceleration, fast response, high sensitivity, excellent tracking performance, low noise, high efficiency, and good cutting quality.

3. Cast aluminum beamAfter artificial aging and solution treatment, it has good integrity, high rigidity, great surface quality, high toughness and ductility, etc. The aluminum alloy has light weight and strong rigidity, which is conducive to high-speed movement and high-precision cutting of various graphics during the fast laser cutting process.

Application

Metal sheet laser cutting machines can cut a wide range of metals, even though highly reflective metals. For instance, carbon steel, stainless steel, aluminum, copper, brass, titanium, nickel, and various alloys. The sheet metal laser cutting machine has extensive applications in decoration, infrastructure, construction, microelectronic, advertising, kitchen appliance, automobile and other equipment manufacturing, and other industries.