#Industry News

How to Choose the Nozzle of the Laser Cutting Machine

How to Choose the Nozzle of the Laser Cutting Machine

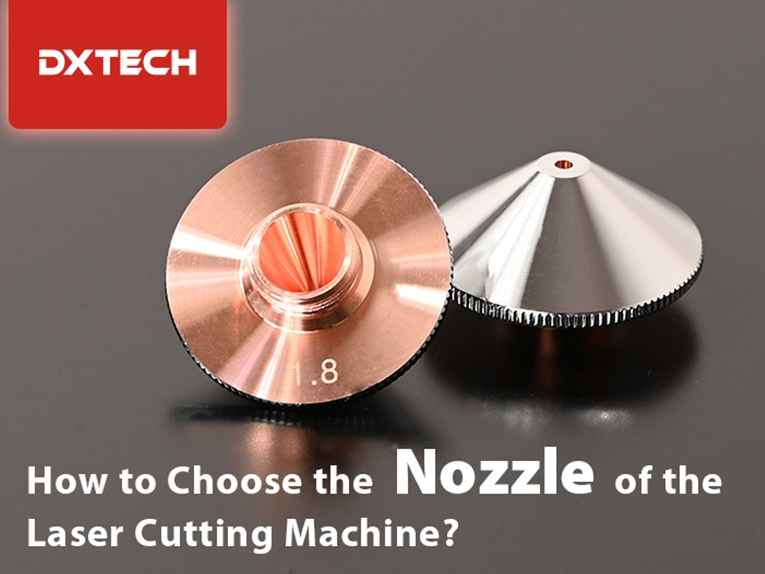

The nozzle is one of the important parts of the laser cutting machine. It is located at the bottom of the laser head and can emit a laser beam and auxiliary gas. Its function is to gather auxiliary gas to form high pressure and release it to the surface of the cutting material and the kerf. At the same time, it prevents pollutants such as slag and smoke from bouncing upwards, thereby protecting the internal lens.

Generally, there are two types of laser cutting nozzles: single-layer nozzles and double-layer nozzles. People do fusion cutting with a single-layer nozzle. That is to say, people use nitrogen as auxiliary gas to cut stainless steel, aluminum alloy, brass, and other materials. Double nozzles are usually used to cut carbon steel, which uses oxygen as the assist gas.

How to choose the nozzle size?

The diameter of the nozzle determines the shape, area, and velocity of the airflow entering the cutout. Therefore, it affects the melt removal and cutting stability.

The faster the gas flow into the incision, the stronger ability to remove the melt. The operator should select the nozzle size according to the laser power and the thickness of the metal sheet to be cut. Theoretically, the thicker the sheet, the larger the nozzle should be used. And the higher the proportional valve setting pressure, the greater the flow rate.

How to choose the nozzle according to the laser power?

1. Laser power ≤ 6000w

When cutting carbon steel, the diameter of the nozzle specification is generally double-layer S1.0-5.0E. And when cutting stainless steel, you can choose a common specification WPCT single-layer nozzle

2. Laser power ≥ 6000w

When cutting 10-25mm bright carbon steel, the diameter of the cutting nozzle is generally double-layer high-speed E-type S1.2-1.8E. If you choose a single-layer fan nozzle, the diameter is generally D1.2-1.8. In addition, if cutting stainless steel, we usually use ordinary specification WPCT single-layer nozzle.

Conclusion

All in all, this article briefly introduces the types and selection methods of laser cutter nozzles. Before selecting, We should know the cutting thickness and processing requirements of the material in advance. If we cannot determine the final cutting effect, we can also contact the manufacturer for cutting tests to see if the accuracy can meet the requirements.

DXTECH has strong technical strength and rich industry experience. We can provide our customers with comprehensive technical support and after-sales service. In the future, we will use our professionalism to create more value for more customers. If you want to get more information, please don't hesitate to make contact us. Looking forward to hearing from you in the future.