#Industry News

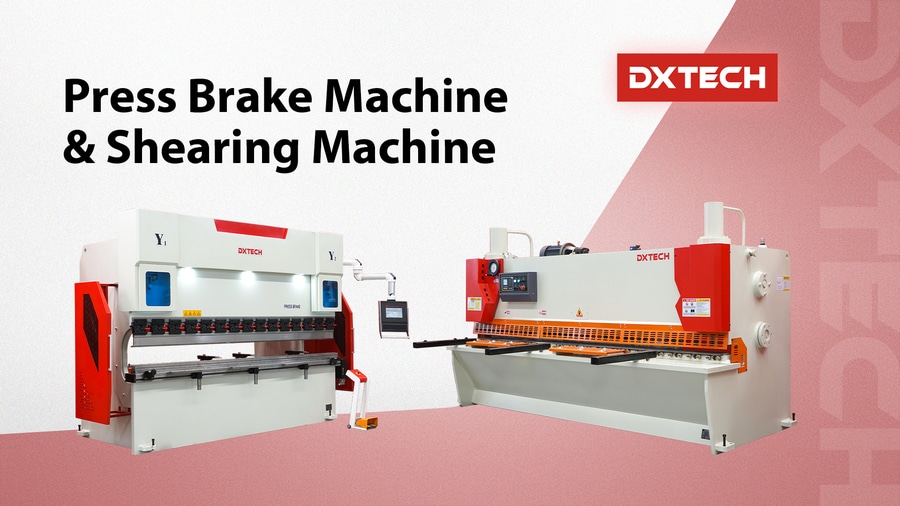

How to Select a Suitable Bending Machine for Your Needs?

How to Select a Suitable Bending Machine for Your Needs?

Driven by the rapid development of the manufacturing industry, bending machines have become indispensable equipment in sheet metal fabrication. With the continuous upgrading and intelligence of manufacturing, bending machines have made significant progress in both technology and application areas. This article will guide you through understanding bending machines and how to select the right one for your needs.

Introduction to Bending Machines

1. Definition of a Bending Machine

The bending machine operates by hydraulically driving a slide, which moves the upper mold up and down. The upper and lower molds are shaped to form the desired bend in the metal sheet. The workpiece is placed between the molds and bent by the downward force of the upper mold.

Bending machines have a wide range of applications, including: automotive manufacturing, aerospace, electronics manufacturing, construction industry, appliance manufacturing,etc.

2.Main Components of a Bending Machine

Upper and lower molds: Used to bend the metal sheet.

Backgauge: Used to position the metal sheet and ensure accurate bending.

Ram: Drives the upper die up and down to perform the bending action.

Hydraulic system: Provides power to drive the ram.

Control system: Controls the various movements of the bending machine for automated operation.

3.How to choose a bending machine

(1).Define Your Processing Requirements:

Material type and thickness: Determine the type of material to be bent (carbon steel, stainless steel, aluminum alloy, etc.) and the maximum processing thickness.

Bending angle and accuracy: Determine the required bending angle and accuracy.

Batch size and frequency: Consider the production batch size and frequency to select the appropriate machine model.

Special requirements: If there are special requirements such as R-angles, V-grooves, etc., inform the manufacturer in advance.

(2).Types of Bending Machines:

Mechanical bending machine: Lower in price, suitable for small-batch and simple workpiece processing.

Hydraulic bending machine: High force, high precision, suitable for bending processing of various materials.

CNC bending machine: High degree of automation, high precision, suitable for mass production and complex workpiece processing.

(3).Key Performance Parameters

Bending force: Select an appropriate bending force based on material thickness and bending length.

Working stroke: Determine the maximum bending height.

Die opening: Choose a suitable die opening according to the material thickness.

Accuracy: Consider repeat accuracy and angle accuracy.

Control system: Select an easy-to-operate and powerful control system.

(4). Brand and After-sales Service

Brand reputation: Choose a well-known brand for better quality assurance. DXTECH is a comprehensive enterprise integrating R&D, production, and sales, with over 16 years of experience in manufacturing advanced CNC laser machines. Our product line, including bending machines, laser cutting machines, engraving machines, and marking machines, has gained popularity among customers in over 180 countries and regions.

After-sales service: Understand the manufacturer’s after-sales service policy, including warranty period, spare parts supply, and technical support. DXTECH provide 2-year warranty, and provide technical solutions within 24 hours. DXTECH after-sales service team of 50+ people comes to the door quickly, returns visits regularly, and gives technical guidance for life.