#Industry News

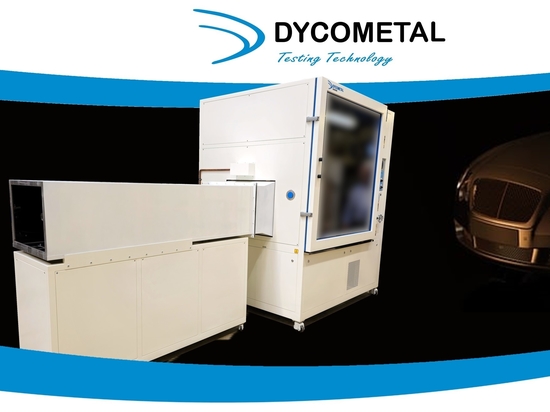

AFA-150/11300, WALK-IN FORCED AIR HEATING OVEN.

Efficient Heating, Perfect Uniformity – AFA-150/11300 Forced Air Oven.

With a volume of 11,300 litres, the oven has a large volumetric capacity to condition a large number of samples in parallel. The internal dimensions: 1850 x 1700 x 3600 mm, also allow for the positioning of very tall samples. The oven has been configured with a heating gradient of 3°C/min, taking into account a full oven: 400 kg of metal, 100 kg of plastic and 20 kg of glass. A total of 520 kg, which means that the floor has been reinforced to withstand this mass. All parameters have been adjusted so that the oven has a maximum uncertainty of +/- 2 ºC, after ENAC calibration.

The oven has also been configured with two access doors, front and rear, for easier sample handling. For viewing the interior, the oven has an observation window in each door, with interior lighting. The doors have been painted in the customer's corporate colour.

The oven has a 120 mm wall pass-through, so that probes or cables can be inserted if the customer needs them.

The interior is made of stainless steel, with rails and hooks at the top for hanging the parts to be tested.

The control by means of programming allows temperature cycles to be carried out and, thanks to the remote control and recording programme, all the test data can be stored so that reports can be made at a later date. Communication is via TCP/IP port. In addition, the system has a weekly time programmer for start-up according to the calendar.

An additional safety thermostat will ensure that the samples are not damaged (safety thermostat on sample).

The oven can be positioned in any location thanks to its wheels for easy movement.

An oven developed for the customer's needs.