#Product Trends

TEMPERATURE TEST CHAMBER UNTIL +300 ºC

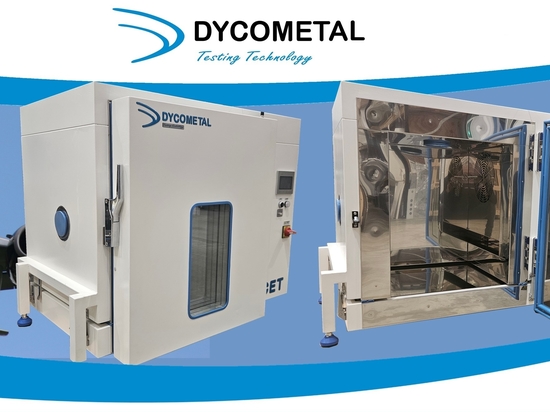

Discover the Revolution in Thermal Testing: CETM-70/263Tge Chambe

The material testing industry is about to experience a transformation with the introduction of our innovative thermal testing chamber, the CETM-70/263Tge model. Specifically designed to be integrated into a tensile testing machine, this chamber offers unprecedented temperature control, covering an impressive range from -70ºC to +300ºC.

Key Features of the CETM-70/263Tge Chamber

Wide Temperature Range

The CETM-70/263Tge allows testing under extreme conditions, from the freezing -70ºC to the scorching +300ºC. This broad thermal range ensures the ability to simulate and analyze virtually any environmental condition, providing valuable and precise data for the development and improvement of materials.

Space and Adaptability

With a volume of 263 liters, the chamber is perfectly sized to fit the space between the columns of the tensile testing machine. This not only maximizes the use of available space but also facilitates integration without significant modifications to the existing equipment.

Innovative Feedthrough System

One of the most significant advancements of our CETM-70/263Tge chamber is its specially designed feedthrough system. This system allows the chamber to be removed without the need to disassemble anything in the tensile testing machine, saving time and effort, and minimizing the risk of damage during the installation and removal process.

Precision Control with Advanced Microprocessor

The chamber is controlled by an advanced microprocessor, ensuring precise and stable temperature regulation. This cutting-edge technology allows programming and maintaining specific conditions with high accuracy, guaranteeing reliable and repeatable test results.

Versatile Applications Beyond the Tensile Testing Machine

Although the CETM-70/263Tge was initially developed for integration into tensile testing machines, its exceptional capabilities make it ideal for a variety of additional applications. Any industry requiring extreme temperature changes can benefit from this technology, including:

Aerospace: Simulation of extreme conditions for testing materials and components.

Automotive: Evaluation of parts under extreme temperatures to ensure their performance and durability.

Electronics: Testing circuits and components under adverse thermal conditions.

Scientific Research: Experiments requiring controlled and extreme temperature conditions.

Conclusion

The CETM-70/263Tge thermal testing chamber represents a significant advancement in the field of thermal and material testing. Its innovative design, extreme temperature capability, and ease of integration make it an indispensable tool for any laboratory or industry looking to improve the accuracy and efficiency of their thermal testing. Don't miss the opportunity to incorporate this revolutionary technology into your testing processes and experience a new era of precision and control.