#Product Trends

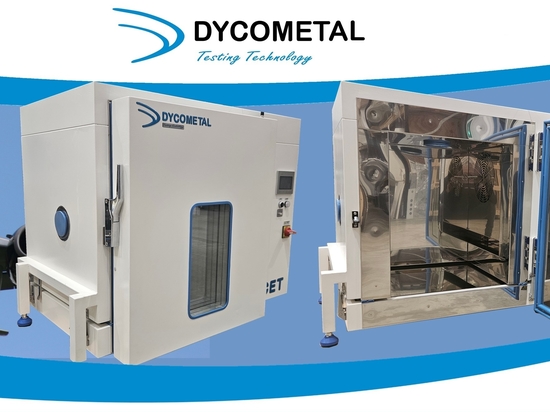

AFA-300/1440T-9, FORCED-AIR HEATING OVEN

FOR THE TREATMENT OF ZINC OR NICKEL-PLATED SURFACES

In order to improve the protective and durability properties of treated surfaces such as zinc or zinc-nickel, a top coat must be applied. This coating is an additional transparent or slightly tinted layer that will act as a barrier against external aggressions, thus increasing the durability of the surface treatment against degradation and oxidation even in the most hostile environments, as well as adding an aesthetic touch.

Our AFA-300/1440T-9 oven has been designed to carry out treatment cycles on a large quantity of dough (800 kg) taking into account the different dimensions of the pieces, which is why, in addition to a reinforced floor, it has 5 trays for a large quantity of dough. In order to carry out this special treatment, the oven must rapidly increase its temperature to maintain it for at least 24 hours. Its refractory steel interior and stainless steel exterior ensure the maximum resistance of the equipment to this extreme process.