#Product Trends

Innovative New Phase Change Materials

Offer Practical Alternatives to Thermal Greases

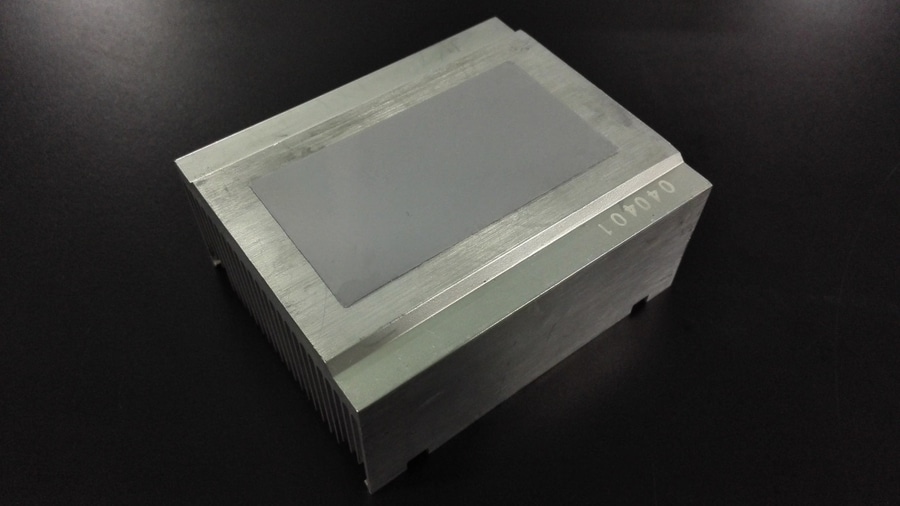

Electrolube has released two new phase change Thermal Management materials that offer high thermal conductivity, low phase change temperatures and low thermal resistance at the interface. Phase change materials are highly suited to the thermal management of electronic assemblies for a number of reasons. They offer efficient thermal transfer, along with enhanced performance with thermal shock cycles and greater thermal protection where temperature spikes can occur, due to their ability to store and release thermal energy (latent heat) during the phase change process.

Providing an alternative to traditional thermal greases, once heated above their phase change temperature the new phase change materials become highly thixotropic liquids that perform equally as well as, but often superior to a thermal grease. The consistency and performance of these new materials avoids possible application and migration problems that can be associated with thermal greases. Electrolube has added two new thermally conductive phase change materials to its thermal management product portfolio: TPM350 and TPM550.

TPM350 has a thermal conductivity of 3.5W/m.K and becomes workable at approximately 50°C. At this 'activation' temperature it changes state to become a lower viscosity material, minimising contact thermal resistance and improving thermal conductivity. Once it cools, it reverts back to its original state. The material’s advanced formulation ensures minimal contact thermal resistance.

TPM550 has a higher thermal conductivity of 5.5W/m.K and an activation temperature of 45˚C. In common with the TPM350 product, TPM550 produces no mess due to its thixotropic characteristics which prevent flow outside of defined interfaces. Both TPM350 and TPM550 can be reworked and their low specific gravity means that more applications can be served per kilogram of the materials, reducing production costs.

The new phase change materials are silicone-free, have an operating temperature range of -40 to +125˚C and are RoHS-2 compliant. TPM350 and TPM 550 are both screen printable and, while they do contain small amounts of solvent to improve wettability on application, this rapidly evaporates following application to leave the solid phase change material on the substrate.

The new phase change materials were unveiled at Electronica in November 2016 with great success. Commenting on the product launch, Ron Jakeman, Electrolube's Group Managing Director, said, “Our range of thermal interface materials on display at Electronica attracted more interest than we could have anticipated, highlighting how manufacturers are fully embracing the importance of electronics protection and turning to Electrolube as a reliable solutions provider for their off-the-shelf and bespoke requirements. The level of enquiries about Electrolube’s new thermal phase change materials TPM350 and TPM550 was especially high, showing the ever increasing importance among visitors of managing heat dissipation effectively in order to achieve maximum reliability."