#Industry News

SUPER-Technopolymer - Elesa engineering plastics standard components

SUPER-Technopolymer - Elesa engineering plastics standard components

Elesa uses the best raw materials and the latest technologies to manufacture its standard components. A wide selection of basic polymers and their combination with reinforcing fillers or other different additives, managed with the Elesa long-term experience, lead to products with improved and guaranteed mechanical and impact strength, creep and fatigue resistance.

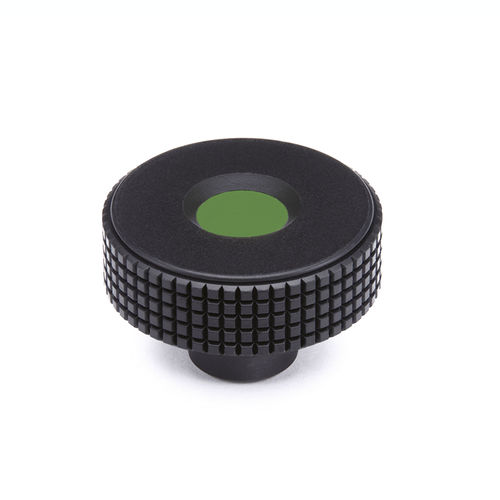

SUPER-Technolopolymer represents the latest evolution for the industrial sector. Its use has led to the development of a range of components with mechanical and thermal properties able to allow their interchangeability with the corresponding metal products, offering the additional advantages of corrosion resistance and lightness typical of plastic materials.

Main advantages of Technopolymer are: high mechanical performance, corrosion resistance, lightness, non-magnetic, low coefficient of friction, maintenance free, thermal insulation and coloured material.

In Elesa, the use of Technopolymer is now a must, that’s why many of its top lines are made of it. Some examples from the Elesa range:

- The EDS components made in conductive Technopolymer which prevents the accumulation of electrostatic charge between bodies with different electric potential;

- The SAN components in special Technopolymer that contains antimicrobial additives and prevents the deposit of any un-healthy organisms, blocking their reproduction;

- The SOFT-TOUCH thermoplastic elastomer surface, which provides a secure and comfortable grip, even in the presence of moisture and grease;

- The ERGOSTYLE line, which meets both functional and aesthetic requirements of the market.