#Industry News

Aeration air flow control on Stendal WWTP

Economical constant and sliding pressure control with Iris® Control Valves

During the upgrade of the Stendal wastewater treatment plant, 20 butterfly valves were replaced by 4’’ (DN 100) Egger Iris® Control Valves with a SCADA control strategy.

As a result, a significant improvement of the oxygen control accuracy could be achieved. The measured DO concentrations are within ± 0.04 mg/l of the setpoint. The precise control and the utilization of the large control range of the Iris® process control valves made it possible to reduce the compressor pressure. With the sliding pressure control used, the pressure could be reduced to 0.42 psi (29 mbar) above the static pressure (blow-in depth). The high control quality and repeatability have a positive effect on the overall process as well as on the energy consumption of the aeration tanks.

In addition to the significant energy savings due to the lowered DO set point, the oxygen transfer could be improved. Furthermore, the diffusers can be flushed more effectively because of to the higher flow capacity of the Egger Iris® valves compared to the former butterfly valves.

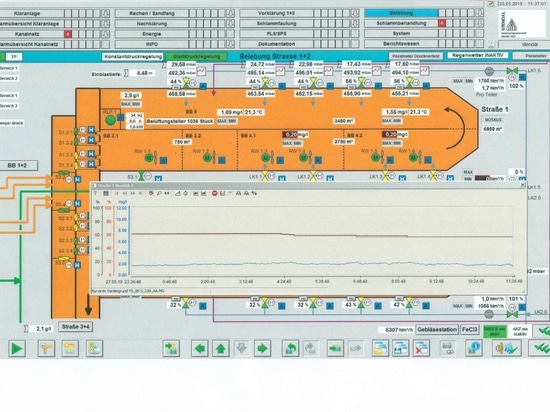

Process control system

The programming of the process control system for the activated sludge air control was carried out by the company S & W Automatisierung Prozeßleittechnik in cooperation with the Stendal sewage treatment plant. A constant pressure control and a sliding pressure control were programmed. The system is designed in such a way that the sewage treatment plant can switch between the two types of control and adjust parameters individually. This allows the potential of the system to be optimally utilized. The oxygen content varies between 1.78 and 1.84 mg/l with a default value of 1.8 mg/l.

There are two control loops for the sliding and constant pressure control: One is the dissolved oxygen control loop, and the other is the control loop for the compressors. The compressors receive only one preset value, which must be maintained.

The pressure downstream of the Iris® Process Control Valves can be read from the graphs of this SCADA print out. This information is helpful to identify any need for maintenance of the diffusors.