#Product Trends

Tin-Side Sensor for Glass Processing

During the manufacturing of float glass, the side that comes in contact with the tin will contain traces of tin and tin oxide. Locating the tin-side is important in this application and many others, including laminating, printing and specialty coating.

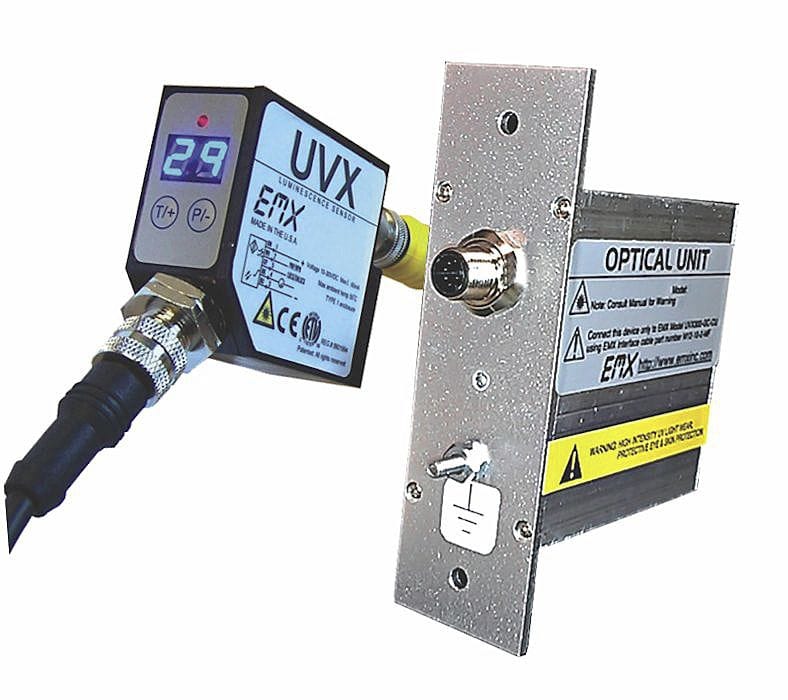

There are several hand held units on the market for this means of detection, but none that can be used as a part of an automated process. The solution is the UVX Tin-side sensor. This sensor reliably verifies the presence of the tin-side of float glass.

How the UVX Tin-side sensor works:

- The system consists of a Control Unit, Optical Unit, 24VDC power supply and interface cable.

- The Control Unit provides a display with a 00-99 range and access to set-up parameters and threshold adjustment.

- The output of the Control Unit is a discrete, NPN/PNP that indicates when the signal level exceeds the threshold setting which occurs when viewing the tin-side.

- The Control unit may be mounted to provide easy access to the controls and the display.

Learn more at www.emxinc.com or email salessupport@emxinc.com.