#Industry News

The Advantage of Additive Manufacturing for Lattice Structure

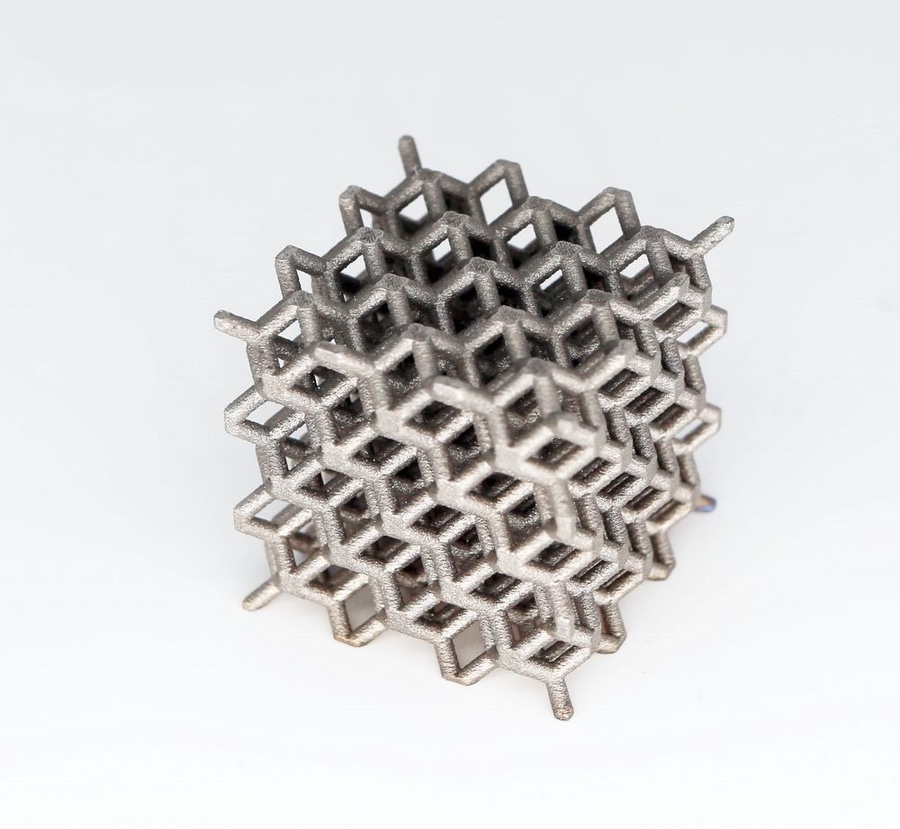

Lattice structure in 3D printing is a useful design that makes parts lighter and stronger. It absorbs impact force more effectively and can be customized according to different requirements.

It absorbs impact force more effectively and can be customized according to different requirements. At present, it is mainly used in aerospace, medical, tool and other different fields, with broad application prospects. At the same time, parts made with a complex internal lattice structure has its unique advantages, and can not be made through the traditional manufacturing technology.

Advantages of lattice structure using 3D printing

Lattice structure is very difficult to produce by traditional manufacturing way. Additive manufacturing not only makes it easy to print lattice structures, but also allows designers to have unlimited imagination in design through the openness of design.

Using lattice structure in design can greatly reduce the amount of material used by removing most of the material in non-critical areas. In the aerospace industry, for example, the application of lattice structure will reduce the use of titanium or nickel materials, saving a lot of cost without sacrificing the structural integrity of the parts.

There is another benefit using lattice structure, that is reducing weight. In many applications, the final weight of a part or assembly, usually the lighter the better. This has many advantages, from reducing fuel use in automotive applications, improving patient recovery time in medical cases, and reducing the weight of aircraft and spacecraft.

Lattice structure implant

The lattice structure of medical implants is an unique design. It improves the adaptability of the implant, speeds up proliferation of cell and makes it much easier for tiny capillaries to grow and connect.

In addition, additive manufacturing also brings a lot of improvement to implants. Due to the integrated molding technology, mechanical properties are greatly improved, which can reduce the incidence of implant failure. Additive manufacturing can print implants at any time through 3D design, shortening the production time and reducing the waiting time of patients.

The lattice structure can be modified and manufactured according to the actual situation of the patient, which cannot be achieved by traditional manufacturing ways. Because of the special lattice structure, the additive manufacturing of the implant is made of ultra-light titanium alloy, which reduces the weight a lot.

Because of the specificity of the lattice structure and these advantages of additive manufacturing, we are able to produce the most efficient implant and other structures with high quality. Welcome to contact Eplus3D for more details about the lattice structure and related cases.