#Product Trends

Inert Gas in Additive Manufacturing for High-quality Metal 3D Printing

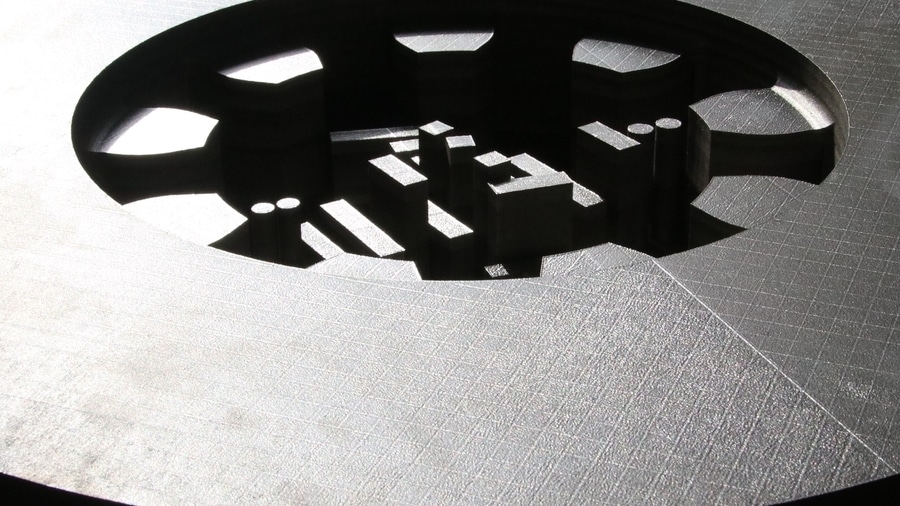

Metal additive manufacturing is a complex process, which is achieved through the interaction and cooperation of different systems.

Metal additive manufacturing is a complex process, which is achieved through the interaction and cooperation of different systems. In addition to laser optics and the quality of the material powder, maintaining an inert gas environment within the metal 3D printer also plays an important role in the quality of metal additive manufacturing.

In order to prevent molten metal elements from reacting with oxygen, metal 3D printing often needs to be operated under the protection of inert gases. The term "inert" means "chemically stable", so metal 3D printing process is suitable for feeding metal powder in an inert gas environment, without being polluted by reactive gases such as oxygen and carbon dioxide in the air. An inert gas environment is an indispensable condition for the powder bed melting process to ensure that the metal parts being processed are not contaminated by air molecules, which would change the physical and chemical characteristics of the final parts.

Common inert gases are argon and nitrogen. Argon gas are applicable to most metal material printing, because it won’t react with active metals such as titanium alloy at high temperature, it is simply for protection, but not involved in production. In addition, metal additive manufacturing process is always operated in a closed space, so the argon gas can be purified and recycled, which has great cost advantage in the manufacturing process, so argon has always been an evergreen material in the field of metal additive manufacturing.

Eplus3D mainly uses argon as the processing environment for the metal additive manufacturing system, because argon is an inert gas and the third most abundant gas in the earth's atmosphere.

All in all, factors that affect the quality and repeatability of metal additive manufacturing include:

1. Excellent laser control to achieve high material quality and component accuracy

2. Qualitative use of powder and process emissions removal for additive manufacturing excellence

3. Stable ultra-low oxygen levels of inert gases to achieve high quality metal additive manufacturing

4. Real-time process monitoring to support quality tracking and information traceability

5. Software that covers the entire additive manufacturing workflow from design to post-processing

Eplus3D provides multi-laser and large-format metal additive manufacturing systems for high quality metal printing, open system for new materials, and self developed software with real-time monitoring etc, so welcome to contact Eplus3D for your tailored AM solutions.