#Industry News

Metal 3D Printing without Support: is it really Feasible?

Supportless printing in the metal additive manufacturing industry refers to a production method in which a support structure is not used during manufacturing.

Supportless printing in the metal additive manufacturing industry refers to a production method in which a support structure is not used during manufacturing. However, the support structure is always needed during metal 3d printing. For example, support is added to the cantilever structure and fine structure to strengthen the strength of the component structure, so as to ensure successful printing.

Metal_Part_1.jpg

The size and structure of the support usually rely on the size and shape of the part being printed. These supports will be "placed" by technicians carefully, to prevent deformation due to thermal stress and to protect printed part to be damaged by scraper. Support also provides extra stiffness to keep it steady. However, removing support will be complex and time-consuming, which will reduce precision of the printed part.

Under this circumstance, supportless printing is put forward. By eliminating the support structure during metal printing, it allows part to be printed independently and the printing accuracy can be improved. However, is it really feasible to metal 3d print without support?

Advantages for supportless printing:

l Shorten printing time

l Save post-processing time and energy

l Reduce material use and environmental impact

In reality, 100% supportless metal 3d printing can not be applied to all shapes, but this may be changed in the future. Without support, a certain angle of overhang can not be achieved with metal 3d printing, as without support, the overhang may be warped due to the residual stress caused from printing, which will limit the application in metal additive manufacturing system. However, the 45° angle has witnessed doubt and challenges. Currently some innovative software and parameter packets can enable users to print overhangs with bigger angles while not affecting part quality.

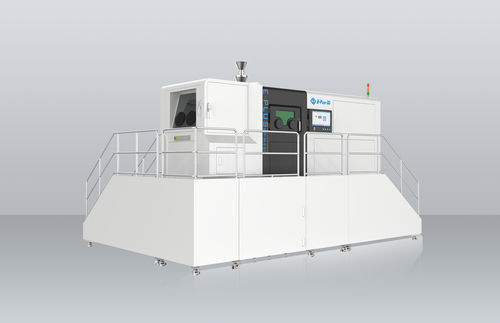

As a leading manufacturer for metal 3D printers and technology with 25 years' experience, Eplus3D is working on developing new technologies and techniques continuously for your long-term success. Welcome to contact us for more AM solutions!