#Industry News

How to avoid jams and gluing defects caused by trim or scrap on flexo-folder-gluers

Corrugated box manufacturers can prevent gluing defects and product jams caused by tab trim and scrap with ERO-ETR Tab Trim Remover

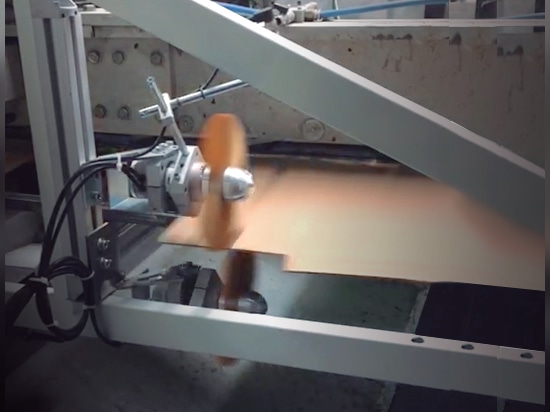

When a Corrugated blank is moving into the gluing station tab trim and scrap can compromise the manufacturer’s joint resulting in box defects. Even the smallest pieces of corrugated trim can be the origin of jams causing machine downtime and production delays on the flexo-folder-gluer as well as problems at the final destination.

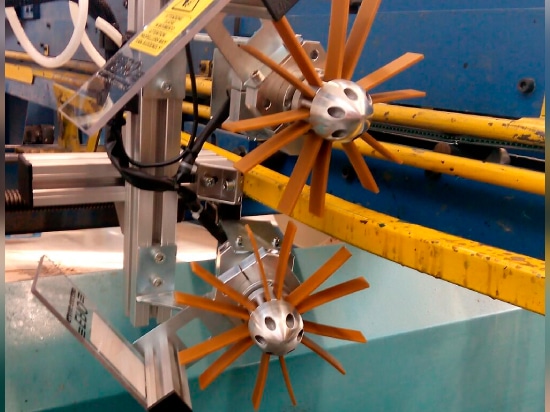

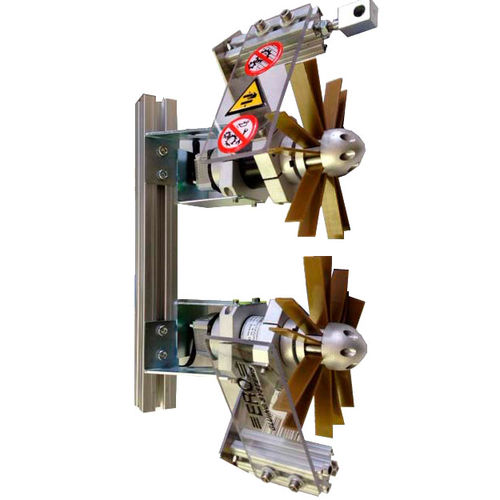

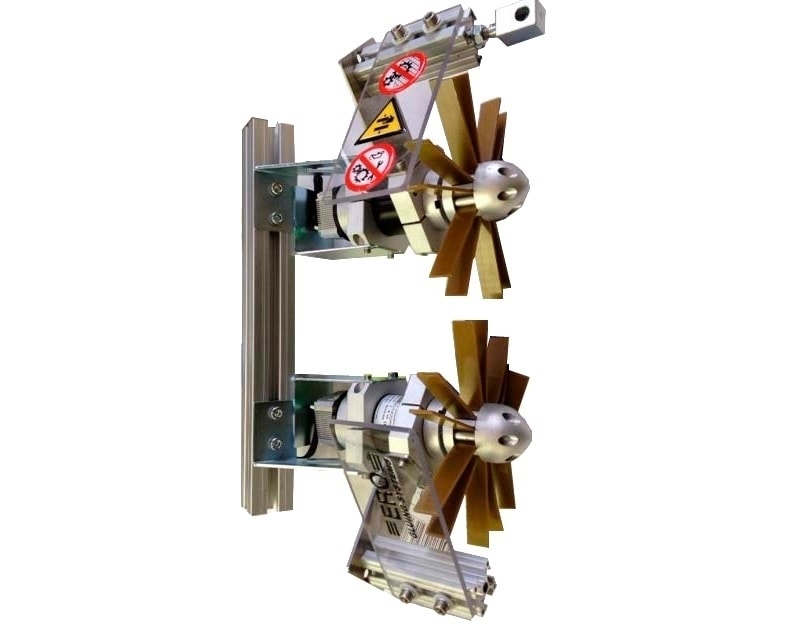

ERO Gluing Systems, always working in a close relationship with box manufacturers, focuses its attention on this common problem that too often affects the overall quality of the box delivered to customers. Therefore, the Italian company designed the ERO-ETR Tab Trim Remover, consisting of two rotating blade sets that remove tab trim before it reaches the gluing station, thus preventing defective boxes.

Compact and lightweight, ERO-ETR can be with ease installed on any flexo-folder-gluer operating in your plant. The unit automatically adapts to the speed of the box flow. The highly durable Vulkollan® brushes provide a long service life in the most demanding production lines.

ERO-ETR includes an electrical cabinet that features a visual System Status Panel. At a simple glance, users will be able to understand the status of their trim remover system, quickly identifying if the system is running, ready to work, or the type of issue occurring.