#Product Trends

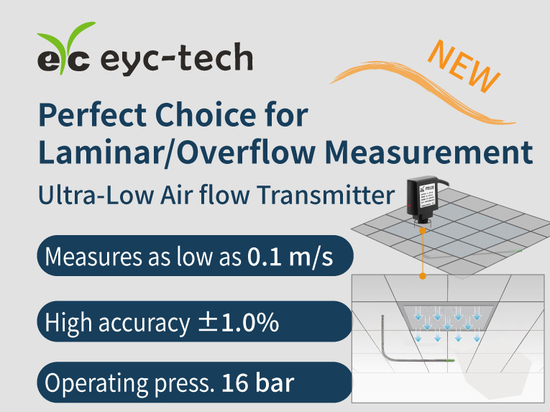

Precision in Small Airflow Measurement: The Advantages of FTE120

In today’s data centers, pharmaceutical industries, and cleanroom applications, precise management of small airflow and air velocity is critical!

In modern data centers and the pharmaceutical industry, precise airflow management and small flow rate monitoring are becoming increasingly important. Low air velocity transmitters can precisely measure the air velocity at each node in the flow field, ensuring even air distribution, which can significantly enhance operational efficiency and safety, such as avoiding localized overheating issues in data centers. Below, we will explore the applications and advantages of the eyc-tech FTE120 Air Flow Transmitter in data centers, the pharmaceutical industry, and cleanrooms.

Applications in Data Centers

Data centers are the core of information technology, requiring highly precise airflow control to ensure servers and other equipment operate at optimal temperatures. The airflow management of computer room air conditioning (CRAC) systems not only affects equipment performance but also impacts energy consumption and operational costs.

1. Need for Precise Airflow Management: Servers and other equipment in data centers require precise cooling; both too high and too low airflow and velocity can cause equipment to overheat or overcool. Low air velocity transmitters can provide more refined airflow data, helping operators precisely adjust cooling systems to ensure uniform airflow distribution.

2. Energy Efficiency and Performance Enhancement: High air velocity can lead to energy waste because excessive airflow may not be effectively utilized by the equipment. Low air velocity transmitters can help optimize airflow and velocity to achieve the best cooling effect, thereby reducing energy consumption and operational costs.

3. Avoiding Airflow Disturbance: The airflow within a data center needs to be stable and uniform. High air velocity can easily cause disturbances, affecting cooling efficiency. Low air velocity transmitters can ensure stable airflow, preventing the decline in cooling efficiency due to disturbances.

Application in the Pharmaceutical Industry

The pharmaceutical industry has extremely high requirements for the production environment, as even minor changes in airflow can affect drug quality and production safety. Therefore, low air velocity transmitters are essential tools for ensuring environmental stability. Laminar flow technology plays a critical role in pharmaceutical production, particularly in sterile operation areas, where laminar airflow prevents cross-contamination between drugs, ensuring the purity and safety of the products.

Certain drugs have strict ventilation requirements in their storage environments. The laminar flow system creates a controlled environment with stable airflow, preventing contamination. By using the eyc-tech FTE120, environmental airflow changes can be precisely monitored, abnormal values can be quickly detected, and appropriate measures can be taken to maintain storage stability, ensuring the drugs are stored under optimal conditions.

Application in Cleanrooms

In cleanroom applications, excessively high airflow in fume hoods and biological safety cabinets can lead to harmful substances being carried out, posing a threat to the safety of the operators. Laminar flow provides stable, uniform airflow, preventing the spread of contaminants and maintaining cleanliness within the cleanroom. In the application of fume hoods and biological safety cabinets, laminar flow ensures the directionality and stability of airflow, further enhancing the safety of the operating environment. Through the precise control of the FTE120, the laminar flow system can better maintain an ideal operating environment, ensuring high standards of pharmaceutical production and the safety of the operators.