#Product Trends

GreCon FORMATOR: Automatic control loop to reduce material fluctuations in MDF panels

The GreCon FORMATOR automatically reduces material fluctuations to a minimum. Thus, the FORMATOR fulfils an important pre-condition for a consistent product quality. The cost of production can be significantly reduced by reducing material consumption and rejects.

A constant material distribution in the mat is one of the most important pre-conditions for a consistent quality in MDF productions. The FORMATOR not only minimises material fluctuations within a production order, but also within the individual panel via an automatic control process. This control process is based on the detection of material fluctuations before the press. The measured data is automatically fed back to the upstream forming tool, the segmented scalper in this case. The segmented scalper immediately regulates the material distribution by specific control of the individual segments. Local fluctuations can be eliminated and a given nominal profile kept constant by lifting and lowering the appropriate segments.

The FORMATOR has meanwhile more than proved itself in different pilot applications. The FORMATOR is a combination of GreCon DIEFFENSOR and segmented scalper, two systems that are successfully established on the market. The GreCon DIEFFENSOR detects the material fluctuations across the entire mat width before the press. With a resolution of 2.5 mm² per measuring point, 400,000 values are recorded per square metre. Thus, not only material fluctuations are revealed, but also metallic and non-metallic foreign objects detected. The steel belt of the press is protected and its life prolonged by diverting the foreign objects out of the process. More than 75 installed systems verify the success of this measuring technology.

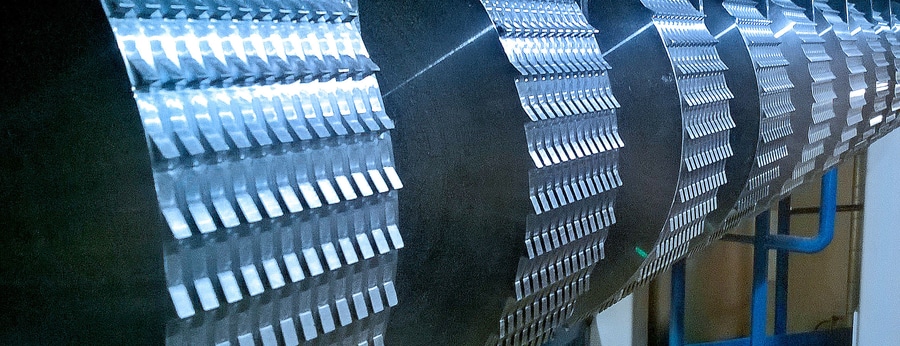

The segmented scalper is a system to optimise the lateral distribution in the forming line. The scalper keeps the preset nominal values by segmented scalping of the formed fibre mat. The removed material is returned to the fibre bin via the extraction system. The width of the measuring sections of the GreCon DIEFFENSOR are exactly adapted to the width of the individual scalper segments. The cutting depth of the individual segments is automatically regulated by the measured values of the DIEFFENSOR. By the combination of GreCon DIEFFENSOR and segmented scalper, synergetic effects in the area of quality optimsation and cost saving can be immediately realised.