#Product Trends

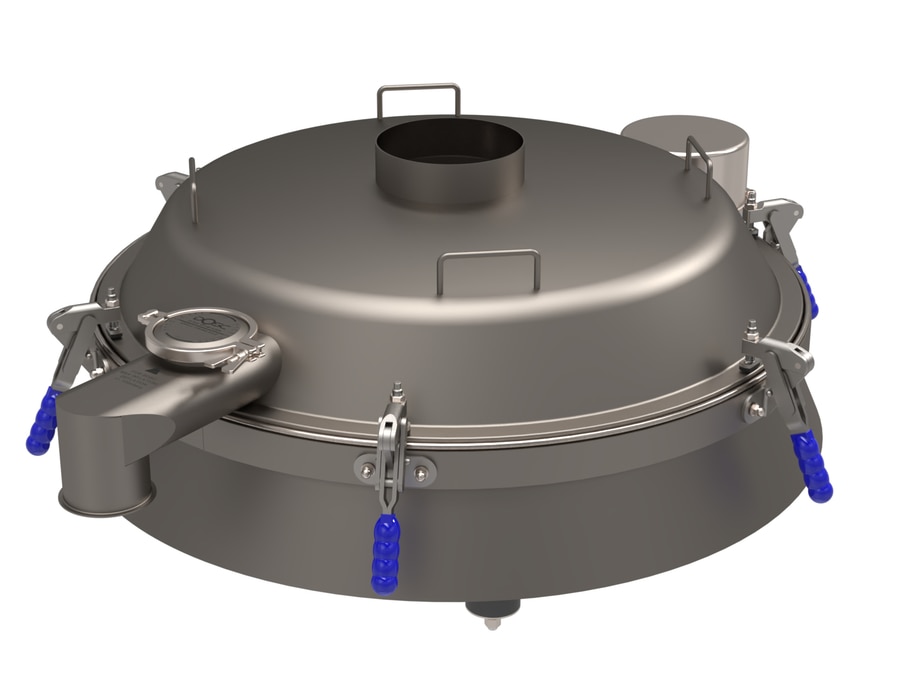

New DOSC: Standard Disc Oversize Outlet Option for Sievmaster Slimline machines

View the new DOSC

Sievmaster DOSC

Our highly regarded Sievmaster Slimline machine range, is now available with a new standard DOSC outlet control option. This new technology replaces the weir plate design with an innovative disc and cap solution. Engineered to optimise throughput, while providing enhanced control and efficiency for bulk application industries. Farleygreene’s next generation in industrial sieving technology.

What is the DOSC?

The DOSC (Disc Oversize Control) option uses a simple and hygienic, plate and cap design. Making it easier for your operator to adjust product flow of oversize material leaving the sieving mesh, via the oversize outlet. Created to enhance screening efficiency and optimise your throughput control.

This is a new, accessible solution that brings lots of new improvements. The DOSC is easily adjustable, before and after your operation, to allow you to select your largest expected oversize product to be ejected. Increasing the rejection rate of genuine oversize and reducing product dwell time on the mesh. This prevents product breaking down and mixing with the fines. Which enhances product efficiency and increases throughput – saving you time and money!

The DOSC is our latest manual oversize control solution which does not require air supply. For a leakproof, automated upgrade option, you need our BOSC (Balloon Oversize Control).

Both BOSC and DOSC options are an easy to integrate solution that can be installed within the footprint of the Slimline machine range.

How it works.

When the DOSC plate is open, free flowing product leaves the oversize outlet and when closed, product builds up behind plate.

The DOSC plate can be manually rotated to allow different amounts of oversize product to escape through the oversize outlet and allows for larger oversize up to 60mm width to be ejected. This can be easily adjusted by one machine operator when the machine is not in operation.

This new feature has an easily adjustable design for varying the amount of oversize product to be ejected (up to 60mm width compared with 10mm of our previous solution). Simply rotate the plate to the desired setting whilst the machine is not in operation.

Features & Benefits

Easy to use, durable and hygienic solution

Designed to be simply adjusted by one operator

Increased precision management of true oversize product flow from the sieving mesh, through the oversize outlet

Prevents blockages and maintains consistent operations

Available with a white or blue metal detectable silicone gasket (Food grade certified to EC 1935/2004)

Available as a standard option in new Slimline machines, with seamless retrofit upgrade BOSC option

Why is our Slimline range being upgraded to include the new DOSC option?

The new DOSC feature provides a modern solution for controlling oversize product flow, reducing downtime, and improving sieving efficiency.

Setting the benchmark for quality and efficiency, whilst keeping pace with your production demands.