#Industry News

Robots out in the field

Key technologies for smart farming

How can food be produced efficiently in the future and, more importantly, who can achieve this? We humans need help if we are to meet these challenges. Smart technologies have the potential to significantly increase efficiency in farming.

Forecasts predict that the human population will grow to between nine and ten billion people by the end of this century. This gives rise to the question as to how food can be produced in a sufficient quantity without endangering valuable natural resources such as clean groundwater and fertile land. And how can it be ensured that in times of acute labor shortage an adequate workforce is available for the intensive work steps involved in harvesting and maintaining crops?

Apart from heavy machinery that cultivates acres of land and fields, farming also relies on extensive manual labor. However, the considerable physical exertion involved in these activities as well as the growing shortage of manpower pose enormous challenges. As a result of today's technological developments, agriculture is becoming ever more digitized and automated and also opens up new, sustainable possibilities. Whether fruit that is carefully picked by robotic grippers, or fertilizers and pesticides that are applied in precisely targeted doses – modern solutions such as autonomous agricultural robots or intelligent attachments make agriculture smart and fit for the future.

Robots help where they can

Smart farming aspires to enable both future-proof and needs-based farming and agricultural management. The goal is to use modern technologies to increase the efficiency of agriculture, to use all resources more sparingly, to relieve people from monotonous work and to produce higher yields. Using computer-supported and networked processes plus machine learning and customized robot functions, focus can be placed on the individual plants instead of the field as a whole. In this way, activities can be targeted more directly as well as implemented more economically and efficiently. A mobile robot with gripper arm can be used for e.g. reliably harvesting fruit that has reached its optimum level of ripeness, determined through camera-assisted sensors. Autonomous field robots, which owing to their low weight protect the arable land, or intelligent cultivation systems, which can sow seed or spread fertilizer exactly where it is needed, also work efficiently.

High-tech for automation

And what technology do agricultural robots rely on? The compactness and the much lower weight compared to traditional large-scale equipment means that the used drive systems need to be as compact as possible. At the same time, the drives must also function reliably and continuously even with major fluctuations in temperature and under the harshest conditions. Furthermore, as drives of sowing disks, flaps, grippers, robot arms or shears, they must supply sufficient power to reliably perform the respective task over countless cycles. At the same time, they should operate extremely efficiently, as the autonomous units usually draw their energy from batteries with limited power reserve. It must also be possible to integrate the drive electronics in networked structures and make intelligent control possible.

Robust solutions from a single source

"These are typical requirements placed on drive systems of the highest class; the right answers are always standard issue at FAULHABER," says Kevin Moser. "Moreover, the drives used in agricultural environments must also be extremely robust so that they themselves function reliably and for the long term under the most demanding conditions. Large temperature fluctuations and strong mechanical loads are the norm in agriculture and horticulture."

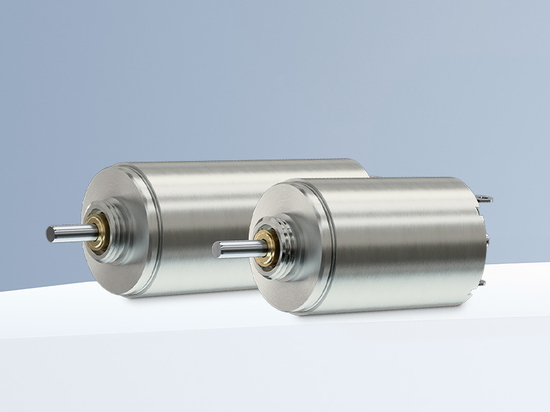

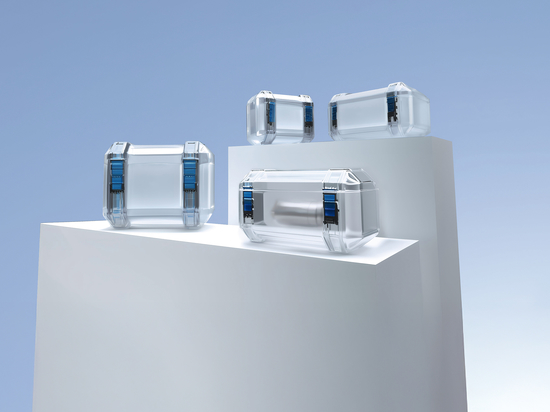

The maintenance-free brushless and especially compact flat DC-micromotors of the BXT series as well as the exceptionally robust and cost-efficient copper-graphite motors of the CXR line meet these requirements. The gearheads of the new GPT series are very well suited for high load transmission under harsh conditions. Extremely efficient, they are also very robust and, thus, ideal for agricultural applications. Optional incremental encoders enable highly precise positioning. Various controllers, e.g., with CANopen interface, are available for the networking of the drive systems. "Drives from FAULHABER are already being used in smart farming," reports Kevin Moser. "They will continue to play an important role for demanding applications in this area."