#Industry News

Smart production layouts

Innovating starting from the workplace

One of the most complex problems for those involved in logistics and production in Smart Factories is also that of preparing production layouts that take into account the appropriate positioning of machines, equipment, materials, tools, technological systems, and service facilities, considering not only the logistical constraints of footprint and shapes, but also technological constraints - think network systems - for production quality.

Whatever is the type of production layout present - and there are 4 commonly recognized ones: product layout, fixed layout, process layout and product family layout - one of the absolutely unavoidable common denominators is the human factor, so it is necessary to always facilitate the operators so that they can do their work quickly, reducing bottlenecks and maintaining high quality standards, of course all in complete safety.

If we refer to the 5S Lean model, we only see benefits for Smart companies: in fact, adopting this method means envisaging a more orderly and standardized management of the workstation, which increases safety, reduces the time to search for objects, optimizes space and allows better communication between operators, not to mention the more organized visual impact.

Therefore, with a view toward continuous improvement of production processes - to move in the direction of operational excellence - order, organization and cleanliness of the workplace are the key words.

Fiam, on the issues of Smart Production, already counts among its solutions for tightening both hand-held and fully automatic solutions that, in addition to integrating technologies that foster the interconnection of the entire production chain for Industry 4.0, provide for the continuous and automatic servicing of screws, avoid unnecessary manipulation by operators and, above all, prevent the loss of screws, the latter a problem that makes workplaces unsafe or worse compromises product quality when it occurs within the components.

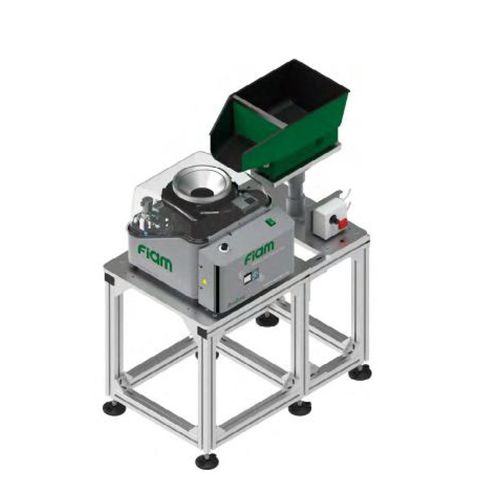

Fiam has gone one step further: to meet the logistical needs of its partners, it has designed and produced structures for operating layouts, useful for supporting screw feeders and hoppers that are used to solve production requirements with high cadences.

These bench structures, designed in the appropriate dimensions for the use destination, are equipped with an aluminum support plate already prepared with holes, which allow the screw feeder to be fixed on it.

The structure is constructed with aluminum profiles that allow cables and tube bundles to pass inside the slots located under the support plate, ensuring a cleaner and more functional operational layout.

To find out all available configurations, see the catalog 73: MCA - Tightening modules with automatic screw feeding.