#Product Trends

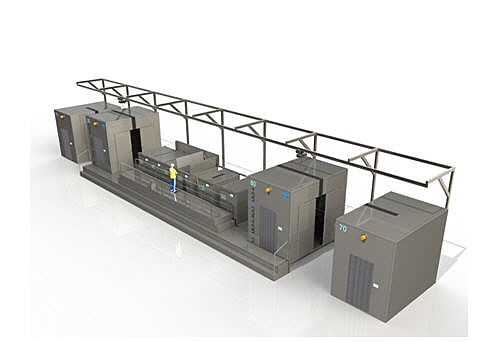

The FinnSonic Optima FPI line to be delivered to Ethiopian Airlines

Aviation giants rely on the technology of Finnish FinnSonic

FinnSonic Oy’s order backlog is at a record high level. Big equipment orders have come in considerable amounts especially from the aviation industry.

FinnSonic Oy has attained an important role as a supplier of aviation industry cleaning systems and fluorescent penetrant inspection (FPI) lines. In the past year, the company has received new orders from the aviation industry the total worth of which is nearly four billion euros.

”The most delightful thing is that the technology we have developed has gained the trust of the top companies in the aviation industry. The amount of air traffic is continuously growing, which has caused the manufacturing and maintenance units to become centralized. It has also increased the need for automatic parts cleaning systems and inspection lines. There are only a few suppliers of such entities in the whole world”, says the CEO of FinnSonic Tea Lehto. According to Lehto, FinnSonic has wedged itself among the world’s top companies, because its strengths lie in intelligent technological solutions, high quality service and solutions, and applications designed according to customer needs.

Considerable deals with global corporate giants of the aviation industry

The year has been very successful for FinnSonic. This fall, we delivered an automatic ultrasonic components cleaning line to Taikoo Engine Services in China. The company is a joint venture of Hong Kong Aircraft Engineering and GE Aviation. This November, we will deliver a large scale FPI line to Ethiopian Airlines. Ethiopian Airlines is preparing for the maintenance of new generation GEnx engines used in, for example, Boeing 787 Dreamliners. The engines spend less fuel, have lower emissions and also have a lower noise level. We have also just made our biggest deal in history with Saab AB Aeronautics for an innovative cleaning system of aircraft parts. Saab’s processes require a high level of cleanliness and even quality – FinnSonic’s automatic cleaning solution makes sure these requirements are met. Other notable future deliveries will be the FPI lines for checking airframe parts to the Boeing Company and SSAMC (Sichuan Services Aero Engine Maintenance Company). FinnSonic is a licensed supply partner of the world’s biggest aircraft engine manufacturer, GE Aviation.

Success has created jobs

The bustling trade has had a direct impact to the company’s employment capabilities. The number of personnel has risen by about 15% since last year. In its processing chain, FinnSonic employs about 80 people in total. The company’s future looks very promising, and even at the moment the company has several recruiting processes ongoing.

Founded in 1979, FinnSonic is a company that is an expert in ultrasonic cleaning and fluorescent penetrant inspection (FPI). The company develops and manufactures solutions for demanding industrial parts cleaning needs and NDT systems in Lahti, Finland. The aim is to develop intelligent, safe and cost efficient solutions to meet customer needs. Over 80% of the production goes to global exports. The clientele includes, among others, British Airways, Emirates Airline, GE Aviation, Finnair, Hella, Metso, Parker, Scania, Sandvik and Siemens.