#Industry News

ATEX infrared thermometer monitors sulfur recovery process

A dedicated, robust solution for monitoring Claus reactors

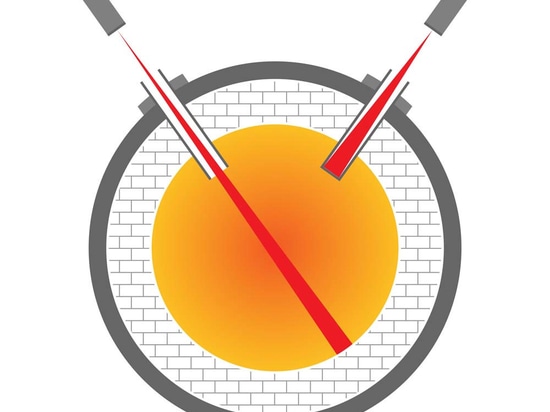

Fluke Process Instruments offers a dedicated, robust solution for monitoring Claus reactors during the recovery of elemental sulfur from process streams. In this setup, ATEX-certified infrared thermometers measure temperatures inside the furnace with short response times. Temperature control of the sulfur recovery process is vital since temperature variations can upset the chemical reaction, causing damage to the fire-clay refractory or even failure of the reactor. Conventionally, thermocouples are used for this application. Such probes must be exchanged at very short intervals, because of the highly corrosive process gases, resulting in significant maintenance costs and downtime. To overcome this problem, thermocouples can be embedded in the refractory or fully shielded by an enclosure. However, this leads to very long response times and inaccurate temperature readings. The tried-and-tested Fluke Process Instruments solution removes the thermocouple at 500 °C, before it can be damaged, and inserts a Raytek Thermalert TX pyrometer in the same opening. To enable this exchange on the fly, the pyrometers come with a hinged housing; both sensor and housing are made of stainless steel. The infrared sensors have a 500 to 2,000 °C measurement range. Equipped with an open or closed end target tube, they measure the refractory brick temperature at the near or far end. Due to the precise temperature data, the refractory lifespan can be extended and operators can optimize their process for fuel savings and higher throughput.